- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- linear systems

Results for

Linear systems - Import export

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

LINEAR GUIDEWAY AND BLOCKS

Request for a quote

DOGUS KALIP METAL FORM SAN VE TIC LTD STI

Turkey

BALL SCREW MODULE Technical Features Body : Aluminium Profile Max. Speed : 0,09 meter / second Driven : Ball Screw Ball Screw : 12x05 Pitch Ball Screw Nut : 12x05 Flanged Shaft : Ø12 Induction Chrome Plated Bearing : Ø12 UU OP Bearing Open Type Accuracy : 0,2 mm

Request for a quote

ROLLON GMBH

Germany

Compact Rail Plus linear guides feature double row ball bearings for higher load capacities and rigid rails with convex raceways and new robust steel sliders with longitudinal protection and floating wipers, Compact Rail Plus has been designed for the most demanding applications in terms of high load capacities, high dynamics and work environment. All while maintaining the self-aligning capabilities that make this product family unique. Sliders are available in four versions: guiding slider (RV); floating slider (RP); extra-floating slider (RU) and rotating slider (RA). Combining two rails with different sliders makes it possible to create self-aligning systems that can compensate misalignment errors on two planes: axial up to 3.5 mm and radial up ±1.3°.

Request for a quote

ROLLON GMBH

Germany

MONO RAIL is a profiled linear rail for high precision under heavy loads. Four rows of balls run in the self-lubricated slider. The running surfaces of the sliders and rails are hardened and polished. Sizes from 15mm to 55mm Standard and flat sliders, with and without flanges Different precision and preload classes Fixing holes from the bottom are available Comprehensive range of accessories, e.g. metal wipers or cover strips MINIATURE MONO RAIL models are mini linear guides with 7mm, 9mm, 12mm and 15mm widths, for particularly noiseless operations. Robust: corrosion and dust resistant Quiet running due to the unique ball channel’s geometric configuration Four-point contacts for equal load capacity in all directions Sliders can be separated from rails without losing balls Long maintenance intervals due to sealed lubrication cycle The MONO RAIL linear guides product family includes profiled linear rails to ensure the highest precision for heavy loads. The availability of sliders...

Request for a quote

ROLLON GMBH

Germany

The O-Rail linear system with rollers ensures the highest flexibility of configuration thanks to the original shape of the FXRG guide, the system basic component, featuring 3 raceways arranged at 90°, over which the R series rollers can run on any one of the 3 raceways. Using a single or multiple parallel guides allows users to achieve several combinations, able to meet all linear motion requirements. O-Rail has been designed as a versatile linear system, ideal for automated applications. It is an easy to assemble system, able to offer a smooth motion even on uneven surfaces.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. The compactness of the closed system makes it ideal for environments without much space between the machine and the ceiling. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. Horizontally mounted, it is mainly used to feed presses installed in series. It extends in both directions, feeding a press in one direction, closing, then feeding another in the other direction. The closed actuator does not occupy space in the two presses, making it possible to feed both with a single system. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

ROLLON GMBH

Germany

Telescopic actuator with a synchronized toothed belt system for effective linear movement and minimal overall dimensions. The wall-mounted system feeds the machine and retracts, facilitating the feeding of machine tools where obstructions to protective doors must be avoided. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK has been a successful innovator and manufacturer of ball bearing telescopic rails and linear slide systems for decades. Our products impress with their precision, high load ratings and long service life.

Request for a quote

ROLLON GMBH

Germany

Compact Rail is a linear system consisting of steel linear rails with induction hardened raceways and high precision radial ball bearing sliders, also made of hardened steel. Thanks to their self-aligning capabilities, Compact Rail linear guides simplify the project, improve the performance and reduce the overall cost of application. Compact Rail linear guides are easy to install on all types of surfaces, including non-machined ones. Compact Rail linear guides feature a robust steel slider with ball bearings, self-centering heads with wipers, longitudinal seals to protect the internal components and a top sealing strip. The slider body is accurately finished with matte longitudinal edge chamfer and a shining ground flat surface. The slider heads are equipped with special slow release felt pads and are free to rotate with respect to the slider body, so that the felts are always in contact with the raceways to ensure optimal lubrication.

Request for a quote

ROLLON GMBH

Germany

The PLUS SYSTEM series of linear actuators consists of highly protected linear units featuring a self-sustaining anodized aluminum structure and a steel re-enforced driving belt. This is a line of exceptionally sturdy and high performance actuators in terms of load, moment control, speed and acceleration. High load capacity,High speed,Low wear and tear,Low friction,Low maintenance.Corrosion resistant version All Plus System series of linear actuators are available with stainless steel elements, for applications in harsh environments and/or subject to frequent washes. The Plus System linear units are made by using extruded anodized Anricorodal 6060 and 6082 aluminum, which houses bearings, linear rails, nuts and bolts and components made of low carbon SS AISI 303 and 404C steel, preventing or delaying corrosion caused by humidity experienced in the environments where the linear units are used.The PLUS SYSTEM series consists of 3 distinct products with different features: ELM,Robot,SC.

Request for a quote

SCHOCK GROUP

Germany

SCHOCK has been a successful innovator and manufacturer of ball-bearing telescopic rails and linear guidance systems for decades. SCHOCK telescopic rails are known for their precision, high load capacities, and long lifespan. Key features of SCHOCK telescopic rails include: Excellent running properties High operational reliability Long lifespan without maintenance Custom connection options Based on individual customer requirements, we develop and manufacture telescopic rails as partial extensions, full extensions, or over-extensions. In collaborative project planning with our customers, we define the product requirements for the telescopic rails. Our customers benefit from a wide selection of rail profiles, mounting systems, comfort features, and high-quality surface finishes, such as SCHOCK powder coating. We supply powder-coated telescopic rails in any desired RAL color, offering you unique design possibilities.

Request for a quote

ROLLON GMBH

Germany

The PRECISION SYSTEM series of linear units are self-sustaining profile systems made of extruded aluminum and steel for the TK series, able to ensure excellent precision. The motion is achieved by means of precision rolled recirculating ball screws with preloaded or non preloaded ball nuts, depending on the models. Using the recirculating ball bearing technology for the screws and the rails ensures great performance to the linear actuators, such as: High precision and high axial forces High mechanical performance Low wear and tear Low resistance to movement High speed (for long pitch screws) The Precision System series consists of 4 distinct products with different features: TH, TT, TV, TK. PRECISION SYSTEM - TH TH linear actuators are rigid and compact, ball screw driven linear units, enabling high positioning accuracy and repeatability in all process phases with optimal performance assured, with a repeatability within 5 µm. Thrust force transmission is achieved by means of...

Request for a quote

ROLLON GMBH

Germany

The ECO SYSTEM units are linear actuators made of a self-sustaining extruded aluminum frame and are driven by a polyurethane belt with AT metric profile steel inserts. Three different sizes available: 60mm, 80mm, 100mm Version available with recirculating ball bearing or roller rails Reduced weight ensured by the light frame and the aluminum sliders High sliding speed The ECO SYSTEM series actuators are offered with two motion systems: ECO SYSTEM – SP Featuring a maintenance free recirculating linear guide rail fitted inside the profile. ECO SYSTEM – CI Featuring four rollers with a Gothic arch outer profile sliding on hardened steel bars placed inside the profile. Main fields of application for Eco System linear units: Automation Packaging Industrial machinery

Request for a quote

ROLLON GMBH

Germany

The SMART SYSTEM linear actuators feature a self-sustaining anodized aluminum frame and steel re-enforced driving belt. This is a series of highly cost effective linear units, featuring high performance combined with a carefully planned simple construction. High load capacity,High speeds and accelerations, High admissible tipping moments, Low friction ,Low noise The SMART SYSTEM series consists of 3 distinct products with different features: E-SMART, R-SMART, S-SMART. SMART SYSTEM – E-SMART .

Request for a quote

ROLLON GMBH

Germany

International patent registered for the CLEAN ROOM SYSTEM line (DIN EN ISO 14644-1) The CLEAN ROOM SYSTEM units are linear actuators with belt driven transmission and are specifically designed for Clean Room applications They are supplied with a certificate issued by the IPA Fraunhofer Institute in Stuttgard, which certifies compliance with class ISO 3 (DIN EN ISO 14644-1), or with class Fed Std 0.01 (FED 209 E). The system prevents particles from being discharged in the environment where the linear unit is located. This has been achieved by using a special straight seal that closes the horizontal opening where the slider moves, as well as by the operation of a 0.8 vacuum pump connected to 2 vacuum pipes located inside the drive head and the idle head. The system allows vacuum to be generated inside the unit so that any particles released when the system is operating are sucked towards the air filtration areas. Clean Room System linear actuators components are all made of...

Request for a quote

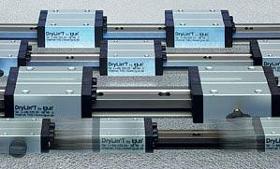

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IGUS® GMBH

Germany

dryve motor control - Connect, select, control... Precise positioning, endless movements, continuous end-to-end movements - simply defined with the new control for drylin® E linear systems from igus®. - No software or app installation necessary - Quick commissioning - Compatible with numerous industrial controls (e.g. Siemens S7 / Beckhoff) - For stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

dryve motor control - Connect, select, control... Precise positioning, endless movements, continuous end-to-end movements - simply defined with the new control for drylin® E linear systems from igus®. - No software or app installation necessary - Quick commissioning - Compatible with numerous industrial controls (e.g. Siemens S7 / Beckhoff) - For stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

dryve motor control system - select, click, control... Travel distances, positions, speeds, operating times - easily defined with the new igus® web-based control system for drylin® E linear systems. - No software or app installation necessary, fast commissioning - Control possible via smartphone (browser), tablet or laptop - Simple and intuitive user interface, control system set up in just a few minutes - Compatible with numerous industrial controllers (e.g. Siemens S7/Beckhoff) - For DC, EC and stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv DryLin® N - Technical data DryLin® linear guide systems in the cleanroom DryLin® N - Applications DryLin® N - Design rules System selection & service life calculation NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. DryLin® N - Low profile linear guide system NK-02-17 DryLin® N - Low profile linear guide system NK-22-17-40 drylin® N - Low profile linear guide system NK-22-17-30 NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor DryLin® N low profile guide systems offer you low profiles in various widths. Like in all drylin® products, the carriage runs without lubrication in anodized aluminum profiles. The material used and the unique design make DryLin® N a cost-efficient and flexible guide system. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Rail made of anodized aluminum 2 Gliding elements made of iglidur® J or J200 3 Carriage made of chromated zinc or plastic 4 Carriage with threaded hole or through hole Advantages: Small installation height between 6 and 12 mm Lightweight Numerous carriage options – also with pretension Maintenance-free, self lubricating Corrossion-resistant Low wear with low coefficient of friction Rails in silver or black anodized When not to use ? When precision below 50 μ is required In high loads over 50 kg drylin® T drylin® R drylin® W When high resistance to chemicals is required drylin® W drylin® R DryLin® N miniature gliding systems - basics DryLinN2010.wmv DryLin® N - Installation video of the gliding elements DryLin_N_Montage.wmv Standard, preload and floating bearing NW 17 = 17 mm rail width The smallest type series of the drylin® N series distinguishes itself by the lowest dimensions and high stressing capacity. This series operates free of lubrication and offers the potential to execute high-speed applications. Variants: Standard, Preload (P), floating bearing (LL) extrem low weight Quiet running Installation height 6 mm up to 50 N load NW 17 Preload (with pretension)The NW 17 Preload model of the drylin® N series displays, in addition to the features of the NW 17, an automatic pre-stressing within the rail. Freedom from lubricants and the potential to execute high travel speeds distinguish this series. 1. NW-01-27 standard 01 with through hole g 2. NW-02-27 standard 02 with threaded hole 3. Preload with through-hole or threaded hole 4. uinjection-molded with through-hole or threaded hole 5. NW-21-27-60P Vollkunststoffschlitten mit Durchgangsbohrung 6. NW-22-27-60P solid polymer carriage with through hole 7. NW-11-27-80 double carriage with through hole NW 27 = 27 mm rail width The installation size 27 offers the largest range of various guide carriages. They vary in the connecting potentials, lengths and precision. The injection-molded types additionally facilitate the stocking and installation. NW 27 Preload (with pretension) Identical version to the DryLin® standard carriage NW-01/02-27 and NW-02-40 respectively. The version injection-molded with iglidur® J offers an enhanced installation-friendliness and easier storage for large quantities. Features like the high wear resistance as well as low coefficients of friction remain unchanged. Over 20 carriage options 9.5 mm installation height 100% lubricant-free iglidur® J plain bearing material up to 500 N Last Best selling linear guide DryLin® N - Low profile linear guide system NK-01-27 DryLin® N - Low profile linear guide system NW-21-27-60P DryLin® N - Low profile linear guide system NK-11-27-80 DryLin® N - Low profile linear guide system NK-02-27 DryLin® N - Low profile linear guide system NW-22-27-60P DryLin® N - Low profile linear guide system NK-12-27-80 1. Standard 02 with threaded hole 2. Injection-molded with threaded hole 3. Standard 01 with through hole NW 40 = 40 mm rail width The dimension 40 defines itself by the rail width of 40 mm and ideally fits standard aluminum profiles. The carriages are available with threaded pin or through hole. The gliding elements are available as clip version or directly injection-molded. Lightweight Installation height 9,5 mm high speeds are possible (up to 5 m/s) iglidur® J plain bearing material up to 700 N Last DryLin® N - Low profile linear guide system NK-01-40 DryLin® N - Low profile linear guide system NK-02-40 drylin® N - low profile linear guide system preload NW-01-40P drylin® N - low profile linear guide system preload NW-02-40P 1. Standard 02 with mounting nuts 2. Injection-molded with mounting nuts NW 80 = 80 mm rail width The largest series in the DryLin® N type series offers the potential to take high loads with low installation height. The largest series also operates free of lubrication and can undertake high-speed applications. The gliding elements can be replaced in the clips option, and the injection-molded option facilitates the installation. Installation height 12 mm 100% lubricant-free Wide torque support up to 1000 N Last Gliding elements made of iglidur® J or J200 DryLin® N - Low profile linear guide system NK-02-80 Telescope system Mounting rails: Anodized aluminum Intermediate rail: Plastic Options: Full extension, over extension (+ 20 mm), partial extension Continuous lengths up to 1200 mm extended total length Lubricant-free Low noise Corrosion resistant From stock DryLin® telescopic rails End caps. The new plastic end caps, suitable for DryLin® N rails, offer „protection against loss“ for the carriages and cover the open sharp edges of the profi les safely and in an aesthetic way. Easy installation Low-priced Dismantling possible High retention force DryLin® N end caps Low profile linear axis - SLN-27-01 SLN-27-01: Linear axis for manual operation with hand wheel (SHT-HR-05-22-15-OG) SLN-BB-27-01: Ball bearing linear axis for manual adjustments with hand wheel 100 / 150 / 200 / 250 mm strokes Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points Feed with spindle Ø 5 and pitch 0.8 and/or 5 mm Manual and motorized operation drylin® miniature linear axis Low profile linear axis - SLN-27-02 SLN-27-02: Linear axis with NEMA11 stepper motor, ball bearing spindle over motor bearing SLN-BB-27-02: Ball bearing linear axis with NEMA11 stepper motor Small (installation height from 22 mm), light and flat Plastic plain bearings in the bearing points M5-thread (5x0,8 mm), steep thread 5x5 and 6x12,7 Manual and motorized operation drylin® SLN low profile linear axis with motor

Request for a quote

IGUS® GMBH

Germany

Lightning fast opening and closing with Zipper E-Chain® und E-Tubes - Zipper E-Chain® satisfy by their practicability and performance. The "zip fastening" function shortens the installation time. The small pitch, the rugged elastic zipper band and the heavy duty links amaze in high accelerations. The Zipper series is one of the most popular igus® E-Chain® series in the sophisticated industrial sectors. Other information Series 047 Inner height hi: 9 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, rip-open along the outer radius Series 07 Inner height hi: 10,3 mm Inner widths Bi: 6 - 64 mm bending radii R: 18 - 48 mm Pitch: 20 mm E-Chain®, rip-open along the outer radius Series 09 Inner height hi: 15 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, rip-open along the outer radius Series 15 Inner height hi: 17 mm Inner widths Bi: 15 - 100 mm bending radii R: 38 - 180 mm Pitch: 30,5 mm E-Chain®, rip-open along the outer radius Series 17 Inner height hi: 32 mm Inner widths Bi: 15 - 100 mm bending radii R: 63 - 125 mm Pitch: 30,5 mm E-Chain®, rip-open along the outer radius Series R07 Inner height hi: 10,3 mm Inner widths Bi: 10 - 50 mm bending radii R: 38 - 48 mm Pitch: 20 mm E-Tube, rip-open along the outer radius Series R09 Inner height hi: 15 mm Inner widths Bi: 10 - 50 mm bending radii R: 48 - 100 mm Pitch: 20 mm E-Tube, rip-open along the outer radius Series R15 Inner height hi: 17 mm Inner widths Bi: 25 - 80 mm bending radii R: 63 - 180 mm Pitch: 30,5 mm E-Tube, rip-open along the outer radius Series R17 Inner height hi: 32 mm Inner widths Bi: 15 - 63 mm bending radii R: 63 - 125 mm Pitch: 30,5 mm E-Tube, rip-open along the outer radius Clean room Class 1 (ISO class 3) for Series 15, tested by the Dryden Engineering Company, California. iF-Design-Award for Zipper-Design UL94-V0 classification on request 58 dB(A) determined at the igus® laboratory, v = 1.0 m/s unsupported, Series 09.50.028.0 Lightning fast opening and closing with Zipper E-Chain® und E-Tubes - Zipper E-Chain® satisfy by their practicability and performance. The "zip fastening" function shortens the installation time. The small pitch, the rugged elastic zipper band and the heavy duty links amaze in high accelerations. The Zipper series is one of the most popular igus® E-Chain® series in the sophisticated industrial sectors. Series 047 Inner height hi: 9 mm Inner widths Bi: 10 - 16 mm bending radii R: 18 - 38 mm Pitch: 13 mm E-Chain®, rip-open along the outer radius Series 07 Inner height hi: 10,3 mm Inner widths Bi: 6 - 64 mm bending radii R: 18 - 48 mm Pitch: 20 mm E-Chain®, rip-open along the outer radius Series 09 Inner height hi: 15 mm Inner widths Bi: 10 - 50 mm bending radii R: 28 - 48 mm Pitch: 20 mm E-Chain®, rip-open along the outer radius Series 15 Inner height hi: 17 mm Inner widths Bi: 15 - 100 mm bending radii R: 38 - 180 mm Pitch: 30,5 mm E-Chain®, rip-open along the outer radius Series 17 Inner height hi: 32 mm Inner widths Bi: 15 - 100 mm bending radii R: 63 - 125 mm Pitch: 30,5 mm E-Chain®, rip-open along the outer radius Series R07 Inner height hi: 10,3 mm Inner widths Bi: 10 - 50 mm bending radii R: 38 - 48 mm Pitch: 20 mm E-Tube, rip-open along the outer radius Series R09 Inner height hi: 15 mm Inner widths Bi: 10 - 50 mm bending radii R: 48 - 100 mm Pitch: 20 mm E-Tube, rip-open along the outer radius Series R15 Inner height hi: 17 mm Inner widths Bi: 25 - 80 mm bending radii R: 63 - 180 mm Pitch: 30,5 mm E-Tube, rip-open along the outer radius Series R17 Inner height hi: 32 mm Inner widths Bi: 15 - 63 mm bending radii R: 63 - 125 mm Pitch: 30,5 mm E-Tube, rip-open along the outer radius E-Chain® selection aids You can find the right E-Chain® quickly by entering concrete parameters and with the aid of a comparison table. Selection aids Installation instructions Joining and separating of the Zipper E-Chain®. Assembly Instructions Application examples Applications in various industrial sectors and in the igus® test laboratory. Zipper Zipper E-Chain® Short installation time: Lightning fast opening and closing of lids with zipper Zipper lid can be separated and joined in any chain link Small pitch for low-noise, silent operation High accelerations: 100 m/s² and more Interior separation possible Zipper E-Tube resistant against chips and dirt Closed E-Tube with zip-open system Protection against dirt and chips Lightning fast opening of the lid in a band Modular design - simple lengthening and shortening Small division for low-noise, silent operation, high accelerations Typical industrial sectors and applications Automatic insertion machines Semiconductor devices Linear motors, handling systems Any kind of technical equipment Measuring instruments Machine tools (Zipper E-tube) Clean room Class 1 (ISO class 3) for Series 15, tested by the Dryden Engineering Company, California. iF-Design-Award for Zipper-Design UL94-V0 classification on request 58 dB(A) determined at the igus® laboratory, v = 1.0 m/s unsupported, Series 09.50.028.0

Request for a quote

WIB SA

Switzerland

As the leading manufacturer of linear guide system bearings, WIB works collaboratively with customers on the development of common and tailor designs, supplying the best-in-class technical and commercial solution for each unique application. Each parameter, including environmental factors, precision requirements, speed, temperature, load, boundary dimensions are thoroughly evaluated during the design and development phase.

Request for a quote

NORELEM FRANCE

France

Shaft support with bore for easy and secure clamping and fastening the guide shafts. Precision guide shafts 21595. Fastening screws 07160 or 07161.

Request for a quote

NORELEM FRANCE

France

Steel 1.1213. Stainless steel 1.4034. Stainless steel 1.4112. Version Steel, ground. Steel, ground and hardchromed, chrome coating 5 10 µm. Stainless steel, ground. The precision steel shafts are generally inductively surface hardened. Note The surface value obtained during the inductive hardening process guarantees high surface wear resistance. Suitable for shaft supports 21565. On request Lengths up to a max. 4000 mm. Accessory Shaft supports 21565. Drawing reference 1) chamfered

Request for a quote

NORELEM FRANCE

France

The readytoinstall compact linear housing consists of extruded aluminium housing, installed linear ball bearing 2151102 and doublesided seal. Recommended shaft tolerance h6. Load rating according to specification of the linear ball bearing. With lubrication hole M8x1. Accessory Precision guide shafts 21595. Fastening screws 07160.

Request for a quote

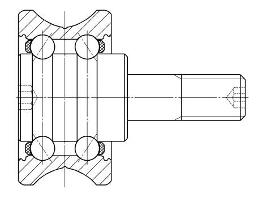

NORELEM FRANCE

France

Housing steel. Cage plastic. Balls steel. Note The linear ball bearings correspond to series 3 of ISO 10285. With doublesided seal. The linear ball bearings have a plastic cage which results in quiet and outstanding running properties. With flange for direct mounting on the housing. Linear ball bearings with doublesided seal should be greased before installation. The specified load ratings apply with the use of hardened and ground shafts. Precision guide shafts 21595. Fastening screws 07160.

Request for a quote

NORELEM FRANCE

France

Housing steel. Cage plastic. Balls steel. Note The linear ball bearings correspond to series 3 of ISO 10285. With doublesided seal. The linear ball bearings have a plastic cage which results in quiet and outstanding running properties. With flange for direct mounting on the housing. Linear ball bearings with doublesided seal should be greased before installation. The specified load ratings apply with the use of hardened and ground shafts. Precision guide shafts 21595. Fastening screws 07160.

Request for a quote

FRANKE GMBH

Germany

For our bearing assemblies and linear systems, we use high-quality lubricants as standard that are suitable for most applications. Special operating conditions require special lubricants. Standard and special greases are available in the respective container sizes from us as accessories. They can be used when our bearing elements are used for the first time or for relubricating slewing rings.

Request for a quoteResults for

Linear systems - Import exportNumber of results

88 ProductsCountries

Category

- Internal transport systems (12)

- Food industry - machinery and equipment (7)

- Automation - systems and equipment (6)

- Robotics (4)

- Bearings - ball, needle and roller (3)

- Machine tools - metal machining (3)

- Plasma cutting machines (3)

- Sensors (3)

- Axles, vehicle (2)

- Conveyor belts (2)

- Joints, hydraulic (2)

- Autogenous welding machines (1)

- Baby-care products (1)

- Bearings, ball (1)

- Bottling and filling - machinery and equipment (1)

- Chemical and pharmaceutical industry - machinery and equipment (1)

- Clamp collars, plastic (1)

- Clothing industry - machinery and equipment (1)

- Construction machinery (1)

- Cutting - steels and metals (1)