- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- mould for casting

Results for

Mould for casting - Import export

MVA D.O.O.

Slovenia

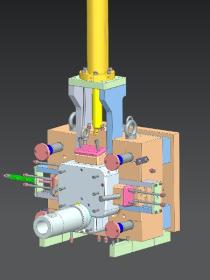

We offer product design consultations, tool designing, mould manufacturing and mould maintenance and service.

Request for a quote

ACKOR MOULD LIMITED

China

We are factory for molds, molding products for plastic,rubber and metal material

Request for a quote

ACKOR MOULD LIMITED

China

We are factory for molds and molding products for plastic and metal material

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd. is a professional ISO9001 certificated Metal Parts & Plastic Parts manufacturer, Located in China Ningbo, Specialized in Services of Sheet Metal Fabricating, CNC Turning & Machining, Tube Bending, Cold Forging & Hot Forging, Plastic Injection Molding & Plastic Extrusion. We outsource aluminum die castings from our friend factory, then do further machining process, finish treatments. sales@mxmparts.com

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd. is a professional ISO9001 certificated Metal Parts & Plastic Parts manufacturer, Located in China Ningbo, Specialized in Services of Sheet Metal Fabricating, CNC Turning & Machining, Tube Bending, Cold Forging & Hot Forging, Plastic Injection Molding & Plastic Extrusion. We outsource aluminum die castings from our friend factory, then do further machining process, finish treatments. sales@mxmparts.com

Request for a quote

PLANSEE SE

Austria

During the aluminum casting process, the metal melt is either poured or pressed into the mold. This process is used, for example, to manufacture cylinder heads, wheel rims and many other aluminum castings. Here, the mold has to repeatedly withstand the metal melt at a temperature of over 600 °C: for inserts made of our tungsten-heavy metal alloy Densimet® and the molybdenum alloy TZM, that's not a problem. The benefits to you: — Shorter cycle times — Top surface quality for your products — Long mold service life — No cracks in the mold insert Tailor-made mold inserts, sprue bushes, cooling inserts and other individual parts as well as semi-finished products for your mold are available.

Request for a quote

EUROBALT ENGINEERING OÜ

Estonia

Metal die casting – is a production technology of castings, in which the alloy under pressure up to 700 MPa quickly fills the mold. Products made in this way can be of different sizes and have weigh up to several kilograms. As a basic raw material normally are used following: non-ferrous metals — copper, aluminum, and their alloys. Die casting makes it possible to obtain high-precision products (along with such technology as powder metallurgy, which allows to obtain sintered metal parts that are particularly hard and wear-resistant). Our company offers the manufacture of parts for LED lighting and other high quality castings. One of the main advantages of die casting is the resistance of finished products to corrosion. The fact is that in the process of their manufacture a strong surface crust is formed, which has a high density and low moisture permeability.

Request for a quote

LBI

France

We manufacture rough or fully machined pouring ladle bushes in high tensile brass

Request for a quote

VLADIMIR PLANT OF RUBBER TECHNICAL INDUSTRY (VLADRTI LLC)

Russia

VladRTI has workshops for industrial rubber goods and metalworking. Our staff is composed of professional employees who are ready to produce any molded RP and design the most efficient mold for this. In this regard, we are always ready to help you and take care of all the nuances of the production of non-standard molded RP. There are two options for the production of molded RP. - the customer has a mold: 1. Based on the product data, we will calculate production cost. 2. We receive the mold and make a test sample (if the mold is not designed correctly and this leads to additional costs, the price is recalculated). 3. The customer should approve the sample (if the sample does not fit, we get feedback on it and make a new one based on additional input. Price changes are possible). 4. We start production of the batch.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Material: custom size: according to drawings Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

XIAN HUAN-TAI TECHNOLOGY & DEVELOPMENT CO., LTD.

China

Our company (Huan-Tai) is rooted in China since mid-90’s. As one of the early runners, we bring value to the table through our capabilities in engineering, quality control and schedule management that meet the high expectations of overseas customers in stability, consistency and predictability. We focus on quality and consistency. Batch production are always consistent with sample. Our Quality assurance: 1. Non-destructive test (NDT): magnetic particle examination (MPE), ultrasonic examination (UE), liquid penetration examination (LPE), X ray. 2. Experienced inspector on dimensions, CMM dimension testing and other tools. 3. To maintain our reputation, we still have excellent return and claim policy even some rare defects. 4. Our prices are always competitive. 5. Spectrometers to assure the material.

Request for a quote

KAMYANKA MACHINE-BUILDING PLANT

Ukraine

Cast iron: weighing up to 350 kg. Steel: weighing up to 200 kg. Colored: weighing up to 50 kg.

Request for a quote

KALEM METAL ENJEKSIYON

Turkey

Countertop built-in stove gas connection part used in kitchens

Request for a quote

YOUNG FOUNDRY - ANATOLIA CASTING

Turkey

Casting iron products, foundry, manhole, gratings, ductile cast iron tree gratings, cast iron castings, contract manufacturing of cast iron casting, outsource for cast iron casting, subcontractor for cast iron casting, drain covers, Casting Channel, polymer Channel, Ductile Iron U Channel Grid for Rainwater System, Ductile Iron Gully Grating, Ductile Iron Channel Grating Water Grates, Cast Iron Sewer Grating for Sewerage System, Ductile Iron Drain Grid, Ductile iron gratings, Ductile Iron Grate and Frame, Cast Iron Drainage Grid EN124, Rain grate, Ductile Iron Locking Grid, sewer cover, DCI Manhole Cover, Ductile Iron Manhole Cover,Square Manhole Cover,Cast Iron Manhole Cover En124 F900 E600 D400 C250 B125 A15, Access Covers, Gully Grates, Kerb Drainage, Surface Boxes, molding etc hs code 732599

Request for a quote

SUN CHEMICAL - COLORS & EFFECTS NETHERLANDS B.V

Netherlands

Lithium Carbonate is a special use chemical used in the steel industry. It serves as a moulding powder when casting steels. It is also usable in the health industry for the treatment of specific diseases. Likewise, the chemical finds application in the glass-making industry. You can extract lithium from a brine pool (underground). Lithium Carbonate is a natural chemical in lakes and seas. The chemical formula is Li2CO3.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Application SMT, BGA, CSP, Flip Chip, LED Detection, Semiconductor, Packaging components, Battery Industry, Electronic components, Automotive parts, Photo-voltaic, Aluminium Die-casting, Moulding Plastic. Ceramics, other special industries.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material:Grey Iron: GG15, GG20, GG25, GG30 Ductile Iron: GGG40, GGG45, GGG50, GGG60, GGG70 Process: Resin sand casting, Film-covering sand casting, Clay sand casting, Hand molding and machine molding Application: Agricultural machinery, Off-shore industry, Printing machinery, Waste treatment machinery, Concrete plant equipment, Packaging machinery, Pumps

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

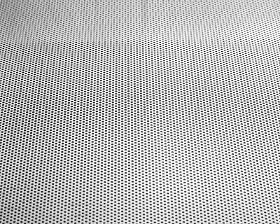

Together with the Fachhochschule Münster – University of Applied Sciences we are working on ALWA PERM (patent No. 2583995). This is a metal-filled casting resin for producing a porous, resin-bound mould. These materials are applicable in the areas of thermoforming, the ceramic industry, intake moulds and devices, pneumatic cushioning, the filter industry, etc. ALWA PERM allows a castable production of porous metallic materials with a binder for the first time. The system offers a highly accurate mould surface reproduction. The profile characteristics goes far beyond the current state of the art. NO MORE DRILLING OF VACUUM HOLES! NO DAMAGE OF THE MOULD SURFACE DUE TO DRILLING HOLES

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

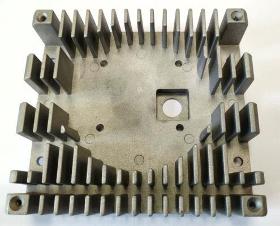

The patented casting resin system ALWA MOULD D consists of two resin components and an aluminium filler. The fast curing of the material allows to produce your own technologically highest quality moulds in just a few hours. As our material is very good castable, compact moulds of any desired volume can be made from our product, such as acrylic baths, boats, etc. (<1 kg – 2500 kg). In comparison to other materials (e.g., glass fibre reinforced plastic), the system is more temperature-resistant, allows castings without air bubbles and does not have to be post-cured. Furthermore, the finished mould is easy machinable (e.g., drilling, milling, grinding, planning, sawing, turning, etc.). ALWA MOULD D moulds can be modified with repair filler, so that a fresh view can be created at an early stage of a new design process and prototypes can be examined at short notice.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Aluminium perforated sheets are used in order to reinforce the casting resin moulds.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA repair filler (art. no. 5100001) is used in order to repair casting resin moulds. The filler is mixed with 1 – 3 % hardener powder.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD SLV is a universal two-component fast casting PU resin for mould making. It is used for the production of milling devices, negatives, product holders, foundry moulds, mould plates, copy moulds, core boxes, pattern plates, casting moulds, prototype parts, supporting moulds and synthetic cast. It consists of a beige-brown low viscosity resin component A (polyol mixture) and a red-brown, low viscosity hardener (component B) based on isocyanate (Methylendi(phenylisocyanat)e = MDI). Two types are available with different pot life: *ALWA MOULD SLV 3 ~ 3 min. pot life *ALWA MOULD SLV 9 ~ 9 min. pot life

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Silicone rubber ALWA SIL SH 22 and SH 33 are silicone impression materials. These materials have extremely high mechanical values. In addition, they are very fast to handle and very easy to handle as well. The two-component silicone rubbers cure at room temperature. After mixing the two components, a low viscosity liquid develops, which crosslinks to a resistant and rubber elastic material. During the crosslinking, no exothermic heat is developed. When 1 – 3 % thixotropic agent is added per component, a spreadable mixture is obtained. Area of application: *Flexible casting moulds *Copy moulds *Moulds with undercuts *Polyurethane casting moulds *Concrete casting moulds

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Below are a few reference objects that we have been able to work on as part of a wide variety of project tasks in recent years: Audi: all RS models since 2000, R8, R8 2015 Bentley: Mulsanne, Bentayga BMW/Mini: Clubman, 3 series Ferrari: 599 GTO Lamborghini: Gallardo, Murcielago, Aventador Mercedes: S-Class, SLS, Actros Porsche: 997, 911 I panel, door trim, center console, greenhouse, interior trim, trim, steering wheel, seats, carpet trim, infotainment system, instrument cluster, mirror, selector lever, switch panel, trunk, engine compartment cover. Wheels, brakes, wheel suspension, exhaust system, engine components, tank, lines. Plastic injection moulding, metal casting, forging, forming, tube processing, painting, galvanic surfaces, lamination, leather covering, upholstery and sewing.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Parting agent for casting, injection moulding, blow moulding and extrusion processes of plastics and elastomers Prevents sticking, for example of excess adhesive and sealant Eliminates creaking and squeaking noises when surfaces made of plastics, elastomers and metals rub on each other For easy fitting of plastic and rubber profiles, e.g. in door and window construction Lubricant for cutting edges of paper, cardboard, veneer or textile machines, etc. Advantages and benefits NSF H1 registered Highly effective due to outstanding surface wetting and formation of separating film with antistatic properties Broad range of uses for long-term lubrication, protection, care and impregnation of material surfaces made of metal, plastic and rubber Minimal consumption through formation of extremely thin films Resistant to water and weathering Long spray tube for precision application MOSH/MOAH-free

Request for a quote

FLUX-GERÄTE GMBH

Germany

FLUX air-operated diaphragm pumps are self-priming and protected against dry running. The pumps are distinguished for their versatility and can be used for virtually all types of media. Available in heavy duty (RFM) or injection-moulded/cast (FDM) version for a huge diversity of applications they are designed for high pressures of up to 8 bars and in addition to other properties they are outstanding for their ease of handling. The 100 % start-up guarantee in every shut-down position guarantees reliability and safe operation. The flow is infinitely variable via the air pressure. In addition the flow rate is easy to calculate. As a result of the integrated silencer the compressed air-operated diaphragm pumps are low noise. In addition the pumps are low-maintenance, in particular if used for pure media.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD P is a cold curing casting resin for the production of porous moulds, slabs and blocks for the ceramic industry. It is a porous and high-strength plastic, which is well-suited for high pressure casting applications. ALWA MOULD P can be used in various areas of the tableware and sanitary ceramics, technical ceramics, plastic mould procedure as well as various filtration processes. The high stability and defined porosity of the material allows highly accurate mould surface reproductions. With ALWA MOULD P various geometric moulds for filtration processes of suspensions can be produced. ALWA MOULD P can be used for ceramic slip pressure casting procedures. In this procedure, water is removed by a filtration process of a clay suspension (slip), so that an increasing clay layer is built on the mould wall over time. The moulds, slabs and blocks of ALWA MOULD P are easily machinable (e.g., drilling, milling).

Request for a quote

NLMK-EUROPE-PLATE

Belgium

Our large range of tool and engineering steels can easily combine toughness with conditioning, shaping and cutting. All these steels respond adequately to your needs of manufacturing hard and resistant tools and moulds. Whether you need them to withstand impact loading or to enable sharp cutting edges, they are made to ensure performance and durability. As a result of the right balance in alloys, our tool steels support high temperature without deformation. Their structure enhances their polishing properties. We can deliver quality tool steels as blocks (raw or machined) or as round bars (raw or peeled). Our extremely large range of thickness renders steels that meet your highest expectations. Applications : Plastic molding dies, die-casting die blocks, blanking and stamping dies, metal cutting tools, extrusion tools, hammers and sledges, etc.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Specifications: Product name: precision machining parts Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. Minimum order quantity: 1000pcs Delivery: 7-30 days Business scope: CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc.

Request for a quoteResults for

Mould for casting - Import exportNumber of results

37 ProductsCountries

Company type

Category

- Die casting moulds (14)

- Casting, steel (5)

- Cast iron items (2)

- Chemical catalysts (1)

- Copper and copper alloys (1)

- Foundries - machinery and installations (1)

- Iron and steel industry and foundries - machinery and installations (1)

- Machine tools, metal machining - parts and accessories (1)

- Metallurgy - machinery and installations (1)

- Moulds, foundry (1)

- Portable electrical pumps (1)

- Precision mechanics (1)

- Roadlaying materials (1)

- Rubber products (1)

- SMALL METAL PARTS (1)

- Silicones (1)

- Steels and metals - machining (1)

- Testing equipment (1)

- Vehicles - mechanical components and parts (1)