- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industry

Results for

Industry - Import export

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pattern with a mountain-shaped spray distribution having gradually tapered edges. Tapered edges overlap to provide uniformity of spray distribution in multiple-nozzle arrangements. Applications Cleaning: Automotive, containers, films, felts, filters, screens, bottles, crushed stones, earth and sand, metal parts, machines, steel plates and pieces Spraying: Etchants, oils, lubricants, glues, solutions, insecticides, herbicides Cooling: Gas, smokes, heat exchangers, tanks, steels, roofs Water screen: Fire protection, heat protection, dust suppression, deodorization

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pattern with a mountain-shaped spray distribution having gradually tapered edges. Quick-detachable design helps to greatly reduce maintenance time. Easy mounting/dismounting with a knurled tab. No falling off of tip or packing when removing the nozzle part. [INVV series (plastic)] Made of high chemical and heat resistant PP (polypropylene). Nozzle tips are color-coded by spray capacity for easy identification. Applications [INVV series (plastic)] Cleaning Etching Stripping For the applications where precise spray alignment and/or periodic maintenance is required

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Self-cleaning nozzle header. Inner brushes for nozzle cleaning are built-in. By rotating inner brushes, nozzle orifices are cleaned thoroughly, and foreign objects inside the pipe are flushed out through the drain. Available in the manual brush-cleaning type (the inner brushes are rotated by turning handwheel) and air-driven automatic type (which allows remote control of spray and cleaning modes). *1) Spray capacity per one nozzle (not per header). Applications [Steelmaking] In Continuous Galvanizing Line (CGL), Electrolytic Galvanizing Line (EGL), Continuous Pickling Line (CPL), and Continuous Annealing Line (CAL)

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Cleaning inside pipes and tubes, moving itself by means of spraying solid stream jets in different directions as driving force. High impact jets effectively remove scale and dirt inside pipes. Applications Cleaning: Pipes, drains, water and wastewater pipes, tubes of heat exchangers and cooling machines Others: Removing scale and rust

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Allows adjustment of spray direction over a range of 50 degrees as desired. [Metal type] Withstands pressure design. Available from 1/8″ to 3/4″ in pipe connection sizes. Use UT-S303 (stainless steel 303) at pressure under 15 MPa (ca. 150 bar), UT-B (brass) under 4 MPa (ca. 40 bar). [Plastic type] Lightweight, high seal performance. Spray direction is adjustable while spraying (up to 0.3 MPa, ca. 3 bar). Use UT-FRPP at pressure under 1 MPa (ca. 10 bar, at room temperature). Cautions for both types: Do not use under conditions where water hammer or sudden change of water pressure occurs. For use with KB and KKBP series nozzles, a different type of UT Ball Joints are required. Inquire with us for details. Applications Accurate nozzle alignment is possible after connected to a pipe. Where large changes in spray direction are required depending on nozzle application such as cleaning and air blowing.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Compact cleaning nozzles for low- and medium-pressure specifications. Available in threaded joint type or pin connection type. In addition to standard types, we can also provide a special-order spray nozzle to meet customer’s tank specifications and applications. Applications Tank cleaning, vessel cleaning

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Low-pressure type rotating nozzle. Solid stream jet provides high cleaning performance. As the nozzle part is movable, it is easy to insert into and eject from a tank or equipment. Compact design allows for installation in a tank with a small inlet. *1) Spray capacity for each model: RJ3-2-Φ7: 103 L/min (at 0.3 MPa, ca. 3 bar)–169 L/min (at 0.8 MPa, ca. 8 bar) RJ3-2-Φ8: 127 L/min (at 0.3 MPa, ca. 3 bar)–207 L/min (at 0.8 MPa, ca. 8 bar) RJ3-4-Φ6: 146 L/min (at 0.3 MPa, ca. 3 bar)–239 L/min (at 0.8 MPa, ca. 8 bar) *2) Reach distance of RJ3-4-Φ6 is approx. 9 meter in radius. Applications Cleaning of tanks, chests, and containers, cleaning inside the chests (material tanks of papermaking)

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Low-speed rotating nozzles for tanks/containers cleaning. Rotation of 5–10 rpm at 0.3 MPa (ca. 3 bar). Maximized contact time between cleaning object and spray liquid achieves higher cleaning effect. High heat-resistant. Applications Cleaning of tanks, containers, filling machines, and conveyors

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features High chemical-resistant rotating cleaning nozzles. Solid stream (ES series) or flat fan-shaped spray pattern (ESV series). Compact and simple design. Rotation is driven solely by the flow of the cleaning fluid. Clean design with little dripping from the nozzle tip even when installed upward. Applications Cleaning by volume of spray flow, not by spray impact Cleaning of tanks and filling machines

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Air booster nozzles producing powerful air blow with small air consumption. Taking in surrounding air, EJA series provides ten times more* blown air than the volume supplied. Graduated scale markings on the nozzle allow for accurate adjustment of blown air volume and intake air volume. Made of stainless steel with high durability. *1/4F EJA 300 Applications Blowing off dust/paint dust, Rejection of inferior products, Blowing off drying Blowing extraneous liquids or powders off of items passing by on the conveyor belt

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features High impact solid stream of air flown from eight holes. Compact design, lightweight. Quiet operation with noise level reduced by more than 10 dB (A) compared to conventional one-hole air nozzle. Max. allowable temperature: [Plastic] 60℃ (140 °F), [Stainless steel] 400℃ (750 °F). Applications Blow-off drying: Blow-off drying for engine block Blowing off: Rejection of inferior products Cooling: Pinpoint cooling for molded plastic

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Long flat air nozzle with 100 mm–1,400 mm in spray width. 13 spray width types are available. Max. allowable temperature: 400℃ (750 °F) Applications Blow-off drying: Blow-off drying after washing, Edge wiper for steel surface treatment, Blow-off drying for engine block Blowing off dust/paint dust/debris, Blowing off inferior products (rejection of inferior products) Cooling: Pinpoint cooling for molded plastic Others: Detachment, Cleaning, etc.

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pneumatic nozzle producing fine atomization with a mean droplet diameter of 60 μm or less (*3). Clog-resistant design. Optimal for spraying viscous liquids. Liquid siphon feed type (liquid pressure device is not required). Use with the liquid pressure device is also possible. *1) Measured at compressed air pressure of 0.3 MPa (ca. 3 bar), liquid pressure of 0 MPa (Liquid siphon feed), and siphon height 100 mm. *2) Free passage diameter of liquid inlet. *3) Measured by Laser Doppler Method. Applications Spraying: Mold release agent, deodorant, oil, surface treatment agent, rust preventive, lubricant, honey, glaze, insecticide, aqueous urea, slurry, other viscous liquid

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Pneumatic slit-laminar nozzle with uniform spray distribution throughout the entire spray pattern area. While multiple-nozzle alignment of conventional pneumatic spray nozzles leaves some spots unwashed, PSN nozzles provide uniform spray distribution and achieve a complete cleaning, leaving no spot unwashed. PSN can be used at a short distance. *1) Measured at compressed air pressure of 0.1–0.4 MPa (ca . 1 bar – 4 bar) and liquid pressure of 0.1–0.4 MPa (ca . 1 bar – 4 bar) for PSN nozzle with slit length of 1000 mm and slit opening of 0.05 mm. Applications Cleaning: Glass substrate, liquid crystal Cooling: Steel plates, moldings Moisture control: Paper, cardboard [Steel making industry] Surface finish process: Precision cleaning for steel surface treatment, Roll cleaning

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pneumatic nozzle producing semi-fine atomization with a mean droplet diameter of 80 μm or more (*3). Clog-resistant design due to large free passage diameter is suitable for spraying factory effluents and waste water. Simple structure, easy maintenance. *1) Measured at compressed air pressure of 0.1–0.4 MPa (ca. 1 bar – 4 bar) and liquid pressure of 0.1–0.5 MPa (ca. 1 bar – 5 bar). *2) Free passage diameter of nozzle orifice for DOVVA-G 70° spray angle type. *3) Measured by Laser Doppler Method. Applications Denitration: Gas cooling Moisture control: Flue gas Combustion: Waste water

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pneumatic nozzle producing semi-fine (and semi-coarse) atomization having a mean droplet diameter of 50μm or more. (*3) High spray impact with thin flat spray pattern and uniform distribution. Liquid pressure type under the liquid pressures of 0.2–0.5 MPa (ca. 2 bar – 5 bar). Large turn-down ratio with stable spray angle. Spray angle of 60° or 80° *1) Measured at compressed air pressure of 0.4 MPa (ca. 4 bar) and liquid pressure of 0.5 MPa (ca. 5 bar). *2) Free passage diameter of nozzle orifice. *3) Measured by Laser Doppler Method. Applications Cleaning: Printed circuit boards, liquid crystal, liquid crystal display, steel plates [Steel making industry] Surface finish process: Precision cleaning for steel surface treatment, Roll cleaning

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Flat spray pneumatic nozzle producing fine atomization with a mean droplet diameter of 100 μm or less.** Ultra-compact size. About 42 mm in total length including control adaptor. Features large turn-down ratio under liquid pressures of 0.1–0.3 MPa (ca. 1 bar – 3 bar). Produces two different spray distributions: uniform spray distribution throughout spray pattern area (when spraying at a low air-water ratio), or a mountain-shaped distribution having gradually tapered edges (at a high air-water ratio). Spray angle of 110 °, 80 °, or 45 °.* Capable of spraying smallest flow rate among all of our pneumatic spray nozzles. Spray ON/OFF can be regulated by switching the pilot air ON/OFF (adaptor type SP) or by turning compressed air ON/OFF (adaptor type SN). *Spray angle measured at compressed air pressure of 0.3 MPa (ca. 3 bar) and liquid pressure of 0.1 MPa (ca. 1 bar). **Mean droplet diameter measured by Laser Doppler Method.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IKEUCHI EUROPE B.V.

Netherlands

Features Extra fine and clear non-turbulent solid stream nozzles with high impact cutting force. Applications Trimming: Paper making Cutting: Timber, food Others: Cleaning of precision machine parts, injection of chemicals, deburring, foaming of beer (jet foamer)

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Extra fine and clear non-turbulent solid stream nozzles with high impact cutting force. Applications Trimming: Paper making Cutting: Timber, food Others: Cleaning of precision machine parts, injection of chemicals, deburring, foaming of beer (jet foamer)

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

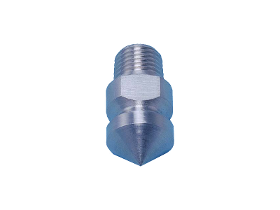

Features High impact solid stream. Convex round inlet protrudes inside the pipe to prevent particles from flowing into the nozzle, reducing clogging. CRP (AL99) series features high-purity alumina orifice providing stable performance with longer life. Applications Cleaning: Wire and felt parts of paper making machines, machinery, parts, vehicles, returnable, containers, bottles

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Our highest impact solid stream. Interior design featuring minimal pressure drop generates large flow of solid stream jet. Impact of turbulent flow inside the piping can be minimized. Applications High pressure cleaning: Wire and felt parts of paper making machines, vehicles, returnable containers, machinery, parts Trimming: Paper making

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pattern with a round superimposed impact area. 7 pcs. of KB series hollow cone spray nozzles are screwed into a very compact header. Capable of generating a large volume of fine atomization. The whirl chamber is formed by a ceramic orifice and closer, which provides excellent wear resistance. Applications Gas cooling, Cleaning, Moisture control, Humidification, Dust suppression

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Square full cone spray pattern with uniform distribution. Wide spray angle of 90–100° provides large spray coverage. Square full cone spray pattern leaves no gaps in multiple-nozzle arrangements. X-shaped whirler provides large free passage diameter for minimal clogging. a Applications Cleaning: Gas, incinerator fumes, machinery, eliminators, screen, tanks, parts, crushed stones, earth and sand Cooling: Gas, machinery, tanks, steels Spraying: Waste water treatment, foam breaking, fire extinguishing, dust suppression

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pattern with a round impact area and uniform distribution. Unique design to produce fine atomization by liquid impinging inside chamber without a whirler. No-whirler design with large free passage diameter minimizes clogging. Spraying axis 90゚ from the axis of the nozzle inlet. For spraying chemicals such as hydrochloric acid, PPS-injection molded AJP are available for excellent chemical and heat resistance. Applications Cleaning: Pre-painting treatment, washing booths, machine parts, gas, incinerator fumes Cooling: Steel plates, copper pieces, gas Spraying: Aeration, foam breaking Others: Applications where re-circulated water is being used or clogging is a concern

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pattern with a round impact area and uniform distribution. Spray angle of 120゚ provides larger spray coverage than other nozzles. Spray capacity ranges from small to medium. X-shaped whirler provides large free passage diameter for minimal clogging. Applications Cleaning: Gas, incinerator fumes, machinery, eliminators, screen, tanks, parts, crushed stones, earth and sand Cooling: Gas, machineries, tanks, steel plates Spraying: Water treatment, aeration, foam breaking, fire extinguishing, dust suppression, sea water desalination

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pattern with a round impact area and uniform distribution. Features smallest spray capacity among full cone spray nozzles. Unique design developed from new engineering concept to produce fine atomization by impinging two inflows inside vortex chamber. Ceramic orifice and closer provide excellent wear-resistance. Applications Spraying: Oils, lubricants, glues, etchants Cleaning: Galvanizing, gas Cooling: Machinery, gas

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Small capacity full cone spray nozzles. Disc whirler is designed to provide uniform spray distribution at small spray capacity. Made of excellent wear-resistant PTFE (polytetrafluoroethylene) and injection molded PVDF (polyvinylidene fluoride). Applications Spraying: Etchants, acid liquids Cleaning with pure water

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Full cone spray pattern with a round impact area and uniform distribution. Spray capacity ranges from small to medium. X-shaped whirler provides large free passage diameter for minimal clogging. Applications Cleaning: Gas, incinerator fumes, machinery, eliminators, screen, tanks, parts, crushed stones, earth and sand, PCB, others Cooling: Gas, machineries, tanks, steels Spraying: Waste water treatment, aeration, foam breaking, fire extinguishing, dust suppression, sea water desalination, etching, chemical treatment

Request for a quote

IKEUCHI EUROPE B.V.

Netherlands

Features Stable spray pattern under low pressures owing to the involute vortex chamber design. Made of highly wear-resistant SiC (silicon nitride bonded silicon carbide). Lightweight as made in all SiC (less than half of metal nozzle). Applications Absorption tower of flue gas desulfurization equipment Spraying slurry

Request for a quoteResults for

Industry - Import exportNumber of results

48 ProductsCountries

Company type