- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- numerically controlled machines

Results for

Numerically controlled machines - Import export

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

Numerically-controlled hydraulic press brake, numerically-controlled hydraulic shearing machine, numerically-controlled machining centres, numerically-controlled lathes and milling machines, mortising machines, presses, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting workstation, paint booth, assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment, testing and programming workstations, etc. With our diverse range of facilities and modular covered areas, we can manufacture practically any type of installation or equipment, with unlimited space and technological expertise. Our multidisciplinary team of highly qualified specialists, combining long-standing experience with the technical skills of youth, guarantees the optimal operation of our equipment and the quality of the facilities delivered to you.

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

In addition to being able to work on site in an emergency to diagnose an unexpected breakdown and repair your installation, we are equipped with: a comprehensive machine fleet (numerically-controlled machining centres, lathes and milling machines, mortising machine, press, drilling machines, rolling machines, semi-automatic welding station, TIG/Plasma/Oxycutting station) meaning that we can manufacture products to measure and supply all your replacement and wear parts in an emergency an assembly workshop (mechanics, hydraulics, pneumatics, electrics, automation), lifting equipment and testing and programming stations, where mechanical and electrical assemblies and sub-assemblies can be produced urgently and with a high degree of flexibility

Request for a quote

THOMAS CONSTRUCTIONS MECANIQUES - TCM SAS

France

With our comprehensive and modern machine fleet (numerically-controlled machining centres, lathes and milling machines), we oversee the quality processes and manufacturing deadlines for the metal and plastic components of the equipment we design. With this know-how and the immediate availability of our machining equipment, we offer a proactive and flexible service which is invaluable for our customers. We can therefore provide a rapid response to any machining enquiries and adapt to any unexpected changes made during projects. However, our key asset is the proximity of our manufacturing workshop to our Design Office, which facilitates the sharing of skills and the optimisation of components. This high-level of reactivity and flexibility also means that we can quickly respond to requests for replacement parts or repairs in case of unexpected breakdowns.

Request for a quote

NOVELTY STEEL

Turkey

CNC machining (Computer Numerical Control machining) is a manufacturing process in which pre-programmed computer software manages the movement of tools and machinery. This process can be used to control a range of complex machinery, from grinders and lathes to mills and routers. With CNC machining, three-dimensional cutting tasks can be accomplished in a single set of prompts. * Gears * Shafts * Brackets * Flanges * Manifolds * Wheels and Pulleys * Bushings * Pins * Housings * Enclosures

Request for a quote

ELEKTRON SP. Z O.O.

Poland

Metal chair frames are the basis of every solid and durable piece of furniture. Without them, in many cases, the design of the chair would be impossible. As a manufacturer of metal chair frames, we focus on the quality of workmanship and precision in production. Metal chair frames manufacturer - Project implementation process Our machine park includes many CNC numerically controlled machines. It is a technology thanks to which we are able to make chair frames of various shapes and sizes while maintaining high quality. The bending of metal chair frames is performed on CNC mandrel benders, which ensures perfect precision and repeatability of production. Thanks to this, our frames are perfectly matched to the other elements of the chairs with which they will be connected. In our production process, chair frames are welded on a robotic welding station. This not only ensures high joint quality, but also increases production efficiency. Robotization

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Turning Parts manufacturing more than 20 years, we have old lathe turning machines, automatic turning machines, and numerical control turning machines, we can optimize the turning processes to make the machining cost to be lowest, accurate tolerance dimensions we use Numerical control machine, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. brass machined parts Brass Machined Parts We have several high precision CNC lathes imported from Japan, equipped with automatic feeding system, which can produce high quality precision brass turned parts.We also have high precision CNC machine tools for turning and milling, which can produce precision brass tuend parts with high concentricity and high finish. Materials of Copper & Brass Parts: T1,T2,E-Cu,H63,H62,H59,CuZn36Sn1... Finish: Tin Plated, Silver Plated, Nickel Plated...

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Valve Spring Locator by CNC Turning service, Material is 4140 steel, Finished by heat treatment to >HRC40 + black oxide. Ming Xiao Manufacturing Co., Ltd engaged in Turning Parts manufacturing more than 20 years, we have old lathe turning machines, automatic turning machines, and numerical control turning machines (CNC Lathe), we can optimize the turning processes to make the machining cost to be lowest, for high precison turned parts or with a certian accuracy required turned parts that we use CNC Lathe to produce, and low tolerance requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. CNC Turned Brass Parts As a professional turning parts supplier from China,we can custom producing all kinds Carbon & Stainless steel turning parts,Copper & Brass turning parts,Aluminum Turning Parts & Machined parts.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Machine Parts manufacuring more than 20years, We have many different type turning machines, automatic turning machines, and CNC turning machines,Swiss CNC turning lathe, Turn & Mill Composite machining Machine, 3,4,5 axis CNC centers. We optimize the turning processes to make the machining cost to be lowest, accurate tolerance dimensions we use Numerical control machine, and low toleracne requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Stainless Steel:SS303,SS304,SS316,SS430 Highest Accuracy:±5μm Surface Finish:Ra0.4 / Rz 3.2 / N5 We provide precision CNC turning & Milling Services for producing Machine Parts for all industries,as long as you can provide detailed drawings and requirements, we can get back to you within two working days. Designs can in many kinds of formats, such as pictures, 3D model, CAD,etc. Price terms: FOB Ningbo, CIF destination port.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co., Ltd engaged in Machine Parts manufacuring more than 20years, we have old lathe turning machine, automatic turning machine, and normal & high precision CNC turning machine,CNC Machining Center. We optimize the turning processes to make the machining cost to be lowest, accurate tolerance dimensions we use Numerical control machine, and low toleracne requested dimensions we use old lathe machine to produce, and small turned parts we use automatic lathe machine to produce. Stainless Steel:SS303,SS304,SS316,SS430 Highest Accuracy:±5μm Surface Finish:Ra0.4 / Rz 3.2 / N5 We provide precision CNC turning & Milling Services for producing Machine Parts for all industries,as long as you can provide detailed drawings and requirements, we can get back to you within two working days. Designs can in many kinds of formats, such as pictures, 3D model, CAD,etc. Price terms: FOB Ningbo, CIF destination port.

Request for a quote

MOLLIFICIO G.R. SRL

Italy

Mollificio GR in San Giovanni in Persiceto (Bologna) produces strip springs that are made using the latest generation of numerically controlled automatic machines, in order to make them extremely performing and meeting all the quality standards of the company. In this section some images of examples of strip springs made at Mollificio GR

Request for a quote

ZETEK SP. Z O.O.

Poland

Cutting elements from material sheets is a basic activity in the serial production of details. The accuracy of their performance depends on the accuracy of subsequent activities, such as e.g. 3D forming or punching. They all contribute to the quality of the effect, and thus also of the finished product. Cutting and progressive dies play an extremely important role in this process . These are tools installed in hydraulic works, which are responsible for making an element of a specific shape and dimensions from a sheet of thin sheet metal. The trimmer should be designed and made with very high precision. It depends on what the effects of his work will be, i.e. the accuracy of mapping the manufactured details. In designing such tools, we use specialized CAD software. On the other hand, precise CNC machining on numerically controlled machines guarantees an extremely accurate representation of the project. Thanks to these possibilities, we offer customers the execution of even very complex

Request for a quote

ZETEK SP. Z O.O.

Poland

Precise CNC machining is currently the basis for the implementation of many production processes. Thanks to it, it is possible to manufacture details that are very complex in shape, such as gears, bearing elements, drive shafts, specialized tools or screws with non-standard parameters. It is used both in serial production and where prototypes are created and individual elements must be made based on technical drawings. It is also irreplaceable in the production of progressive tools . Precise CNC machining with the use of numerically controlled CNC machines also guarantees a very high repeatability of the elements made. At the same time, it reduces the time of their production and contributes to the economic use of materials, and as a result - to lower production costs. Such effects are determined both by the preservation of the set parameters throughout the production period of the series and the elimination of human errors. Precise CNC machining is also one

Request for a quote

MOVINGROUP S.R.L.

Italy

We develop and produce the most advanced engineering solutions for businesses in order to support and assist them in solving technical challenges and developing creative products. We are experts in the design and manufacture of plastic components utilizing high-precision numerical control machines, ensuring a high level of finish on the end product. Our products can be completely customized, have non-standard dimensions, and can be produced in small quantities. Prototyping, functional and assembly tests, and rapid delivery are all available.

Request for a quote

TARET

Poland

We bend metal sheets on numerically controlled (CNC) bending machines from AMADA, LVD, PROMECAN, DURMA. In addition to bending sheets in a straight line, we also perform profiling on cylinders and bending pipes and profiles. We have 9 CNC press brakes, on which we can bend elements up to a length of 4 meters. Our largest press has 4 meters of working length and 320 tons of pressure. In the near future, our machine park will be enriched with a robotic station for bending sheets with an Amada press with a length of 4 meters and a pressure of 220 tons.

Request for a quote

NURER MAKINA LTD STI

Turkey

CNC Borverk, often referred to as CNC Boring Mill or CNC Boring Machine, is a specialized type of machining equipment used for enlarging or finishing pre-drilled holes with precision and accuracy. Borverk is the Swedish term for boring, reflecting the origin of this machining process. The CNC prefix stands for Computer Numerical Control, indicating that the machine's movements and operations are controlled by a computer program. CNC Borverk machines are commonly used in industries such as aerospace, automotive, oil and gas, and general manufacturing, where the production of large, complex parts with high precision is required. These machines are particularly suited for machining large workpieces that cannot be accommodated by traditional drilling or milling machines.

Request for a quote

MECANUMERIC

France

MDA : A water jet cutting equipment range fully adapted to food cutting Refer to the exemples of applications : Bakery pastries Cocktails Fruits and vegetable cutting Fresh or frozen cakes cutting MDA : A water jet cutting equipment range fully adapted to food cutting This new product range allows the cutting of food products such as pastries, fish, catering products, sandwiches… Based on a welded mono bloc frame and a mobile gantry in stainless steel, respecting the sanitary constraints of the food industry, the MDA offers a mobile table for a loading and unloading in concealed time. The very high pressure KMT H2O generator unit is integrated in the equipment or removable. The implemented technologies originating from the precision mechanics guarantee the longevity and the performances in the long time. The driving is realized by the MECANUMERIC CN7100 numerical control with Human Machine Interface (HMI), color touch screen, under Windows XP Pro, USB connections, Ethernet...

Request for a quote

EZSO, LLC

Russia

With our equipment you can make flight screws (feathers) up to 50 mm thick of any geometry and from any steel grade. The equipment is fitted with modern CNC control and software, which allows you to maintain accurate repeatability and ideal geometry of the flight screws. SPECIFICATIONS Overall dimensions of the press, L/W/H - 3200 mm / 1350 mm / 1500 mm Overall dimensions of the control unit, L/W/H - 1000 mm / 800 mm / 1650 mm Unit weight ready-assembled - less than or equal to 8000 kg Working pressure in the hydraulic system - 21 MPa Maximum pressure in the hydraulic system - 25 MPa Nominal press power - 100 tons Maximum short-term power - 110 tons Mains voltage - 380 V Power consumption - 22 kW Outer diameter of the coil - not limited Maximum flange height - 680 mm Maximum flange thickness - 2 mm - 50 mm Maximum flange pitch (with standard equipment) - unlimited

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

METMANN

Spain

High temperature heater for pest control and drying processes Our high temperature electric heater model KILL MANN is an equipment designed and manufactured for pest control and drying processes where hot air at high temperature is required. The electric heater can be placed inside or outside the space that we want to disinsect or dry. The hot air will be directed towards the room repairing the heat evenly in all the corners where the insects can be found. Heat sensitive material should be removed from the room as the temperatures reached can damage them. The insects will die at a temperature of 48 °C for 150 minutes but if we increase the temperature to 55 °C for 60 minutes it will cause the elimination of the pest in all its stages (egg, larva, chrysalis, fully developed insect) by destroying the proteins from the body, a decisive factor in successfully eliminating the pest.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

For many years now, the CNC PILOT has been proving itself in daily use on lathes and has earned a reputation for convenient NC programming. With the introduction of smart.Turn, HEIDENHAIN has made yet another step forward toward greater ease of use. Easily understandable program entry in forms, default setting for global values, numerous selections and straightforward graphic support ensure fast and easy operation. The new smart.Turn interface is based on the proven HEIDENHAIN-DIN PLUS. Because smart.Turn produces DIN PLUS programs. It provides both the NC programmer and the machine operator with all relevant information during program run. Thanks to its flexible design and numerous programming features, the CNC PILOT always gives you optimum support. Regardless of whether you are manufacturing single parts or batches, simple or complex workpieces, the CNC PILOT always provides the right support. The CNC PILOT is characterized by its simple operation and programming.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

For more than 35 years, TNC controls from HEIDENHAIN have been proving themselves in daily use on milling, drilling and boring machines, as well as machining centers. While the controls have undergone continuous development during this period, the basic operational technique has remained the same. You will find also these principles implemented in the TNC 640, the HEIDENHAIN contouring control for milling and milling/turning operations: shop-oriented programmability with graphic support, many field-proven cycles and an operational design you'll recognize from other HEIDENHAIN controls. Shop-oriented programming You program conventional milling and drilling operations, and with the TNC 640 also turning operations, yourself at the machine, in plain language dialog—the workshop-oriented programming language from HEIDENHAIN. The TNC 640 provides you with optimum support with practical prompts, questions and expressive graphical aids—for turning operations, too.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Thanks to its flexible operating concept – workshop-oriented programmability with HEIDENHAIN conversational programming or external programming – and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for series and single-part production tool and die making manufacture of machines research and development prototype production and testing facilities repair departments educational and training institutes The TFT 15-inch color monitor shows a clear overview of all relevant information for programming, operating and inspecting the machine tool and control such as program blocks, comments and error messages. More information is provided through graphic support during program entry, test run and actual machining. The selectable split-screen display shows the part program blocks in one half of the screen and the graphics or the status display in the other half.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TNC 620 is compact and easy to read. The TNC 620 is a compact but versatile contouring control for up to five controlled axes. Thanks to its flexible operating concept—workshop-oriented programmability with HEIDENHAIN conversational programming or offl ine programming—and its scope of features, it is especially suited for use on universal milling, drilling and boring machines for the following: Series and single-part production Toolmaking Machine building Research and development Prototypes and pilot plants Repair departments Training and education facilities And it offers the applicable features both necessary and helpful: Universal milling machines Free contour programming Milling cycles for complex contours Fast presetting with HEIDENHAIN touch probes Drilling and boring machines Cycles for drilling, boring and spindle alignment Cycles for linear and circular point patterns Five-axis machining with swivel head and rotary table

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

For many years now, the MANUALplus has been proving itself in daily use on cycle lathes and is characterized particularly by convenient manual machine operation. Application-oriented cycle programming enables the machinist to create and edit programs rapidly and effi ciently on the lathe. The introduction of the MANUALplus 620 extends the area of application to single-spindle CNC lathes. With the smart.Turn operating mode, HEIDENHAIN has made yet another step forward toward greater ease of use. Easily understandable program entry in forms, default setting for global values, selection options and straightforward graphic support ensure fast and easy operation. The new smart.Turn interface is based on the proven HEIDENHAIN DIN PLUS: smart.Turn creates DIN PLUS programs and provides both the NC programmer and the machine operator with all relevant information during program run.

Request for a quote

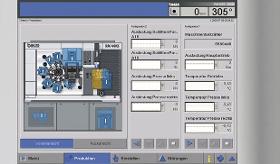

OTTO BIHLER MASCHINENFABRIK GMBH & CO. KG

Germany

VariControl VC 1 - One control platform for all tasks With the VariControl VC 1 machine and process control system, Bihler emphasizes the keywords „Ease of Use“ and „Process Safety“ at a new, higher level. With state of the art software and hardware features, the intelligent control system guarantees greater efficiency in your production. The highly flexible control platform allows you to easily control even the most complex automation solutions in the field of stamping and forming assembly technology – on all Bihler machine types. The integrated „bASSIST“ diagnostic and online help system assists your machine operator just like a second operator at his or her side. Videos, graphics and individually created data simplify adjustment, setup and maintenance operations significantly. The continuous monitoring of all machine and tool functions guarantees maximum machine availability.

Request for a quoteResults for

Numerically controlled machines - Import exportNumber of results

25 ProductsCountries

Company type

Category

- Machine tools - metal machining (5)

- Numerical control systems - minicomputers and mainframes (5)

- Motor mechanics - hand tools, non power (3)

- Turning - steels and metals (3)

- Precision measuring instruments (2)

- Armchairs (1)

- Compactors and crushers (1)

- Folding machine tools (1)

- Mechanical engineering - custom work (1)

- Milling - machine tools (1)

- Milling and turning of rubber and plastic (1)

- Pest control - machines and equipment (1)

- Spiral springs (1)

- Stainless steels (1)

- Steels and metals - machining (1)