- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- robot integration

Results for

Robot integration - Import export

MTA ROBOTICS AG

Switzerland

The mta OEM soldering robot for integrator can be used for semi or fully automatic operations of selective point to point soldering from above. Thanks to its unique concept, the OEM robot is delivered to the system’s manufacturer with a process guarantee. The OEM robot can be equipped with any of mta’s soldering heads: soldering iron, induction, microflame; except for the mta MLH45 laser head. The 3 or 4 axes of the OEM robot are fully programmable through the mta-MotionEditor software, including soldering parameters such as: Solder quantity, wire feed speed, preheating/postheating times, automatic tip cleaning cycle intervals and other parameters for each soldered point. With its flexible and modular concept, the OEM robot can be fully and easily integrated into a production line.

Request for a quote

SYNERLINK

France

EL PAL is a secure robotic cell for palletizing open trays, closed trays, plastic crates, bundles, etc. This robot is integrated with existing equipment to increase efficiency by having an optimized pallet. The pallet settings are indexed according to your cases. The interlayer pick-up function is incorporated within the gripper. EL PAL is totally designed to be interfaced with any SYNERLINK machines.

Request for a quote

SAMSYS GMBH

Germany

The OnRobot force-torque sensor provides accurate force and torque measurement along all 6 axes. This gives you precise control during difficult assembly, polishing, grinding or deburring. In addition, the HEX software offers path recording, force control and special functions for insertion. This reduces the integration time for your production line. Our sensors are suitable for most of the industrial robot arms currently in use. Common applications are polishing, grinding, deburring and assembly. They can also be used for teach-in applications and collision detection. Currently available models: HEX-E – High precision, HEX-H – Low deformation, HEX-E QC, HEX-H QC Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Request for a quote

SAMSYS GMBH

Germany

The silicone gripper Soft Gripper from OnRobot can pick up a wide variety of irregular shapes and delicate objects. This makes it ideal for pick-and-place applications. The Soft Gripper is particularly suitable for applications in food and beverage production, manufacturing and packaging. The gripper is available with three interchangeable silicone-coated suction cups. Whether eggs, fruit, bottles or cans – this silicone gripper from OnRobot makes food and beverage automation easier. Like all OnRobot grippers, the Soft Gripper can be seamlessly integrated into the robot of your choice. The Soft Gripper operates without an external air supply, so there is no additional cost or complexity, and no dust or noise is generated as with conventional grippers. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Request for a quote

SAMSYS GMBH

Germany

With the new intelligent OnRobot screwdriver for light industrial, cooperation and assembly robot you can easily automate processes. Intelligent error detection and handling of multiple screw sizes ensures consistent results and drastically reduces your cycle time. Seamless integration with the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. Functionality Due to the simple connection of the screwdriver and the operation and programming via the own URCap (only applies to Universal Robots) the grippers are ready for use in the shortest time. In addition, the connection time is reduced by the OnRobot quick-change system Quick Changer and Dual Quick Changer.

Request for a quote

SAMSYS GMBH

Germany

Since the vacuum gripper VG10 does not require a compressor or an air supply, it is a compact and easy to move solution. This makes your production line more flexible and saves maintenance costs. It has flexible arms and an adjustable vacuum. This allows the VG10 to handle different objects in many different sizes. Furthermore, your efficiency is further increased because it is a double gripper. This means you can control the right and left side of the vacuum gripper independently of each other. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. The vacuum gripper is equipped with double gripper functionality, a tool changer and various common suction cup attachments. In addition, there are many third party suction cup attachments on the market to suit any application.

Request for a quote

SAMSYS GMBH

Germany

The compact, electric vacuum gripper VGC10 offers infinite adjustment possibilities. It also has optional suction cups for almost any application. The VGC10 is smaller than the VG10, making it suitable for tight environments where it can expand your automation capabilities. With the same payload, but half the weight of the VG10, the VGC10 can lift small, bulky and heavy objects even with a smaller robot arm. The VGC10 has two independently controlled air ducts. This allows it to be used as a double gripper with pickup and release in one action. This further increases efficiency and reduces throughput time. Since neither compressor nor air supply is required, this compact electric grab is easy to move. Easy programming allows it to be quickly reassigned, providing greater production flexibility. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc.

Request for a quote

SAMSYS GMBH

Germany

The Intelligent Robot gripper RG2-FT is a modern gripper with additional sense of touch and intelligence. It has an integrated force/torque and proximity sensor for extremely precise automation. This enables real collaboration with human users and supports them like a helping hand. Insertion is faster and more precise. For example, this gripper can easily insert pins, which would be difficult for humans. Due to the advanced sensor technology, the gripper allows the robot to feel during assembly when a part is correctly assembled. The RG2-FT Robot gripper offers high productivity and rapid deployment, saving technicians many hours of man-hours during integration. It´s the world’s first robot gripper with integrated force/torque and proximity sensors that can see and feel objects to ensure extremely safe handling

Request for a quote

SAMSYS GMBH

Germany

The 3FG15 3 finger gripper is ideal for gripping a wide variety of cylindrical objects. For example, for the feeding of CNC lathes. Due to the design of the gripper, workpieces are automatically centred. This ensures quick readiness for use as well as a strong, stable grip and precise placement. With a payload of up to 15 kg, the 3FG15 competes with larger, bulkier and much less flexible finger grippers. Like all OnRobot grippers, the 3FG15 can be seamlessly integrated into the robot of your choice. Seamless integration into the robot of your choice. For example Universal Robots, Nachi, Doosan, Yaskawa, TM Robot, Kawasaki, ABB, Kuka, Hanwha, Fanuc. Due to its flexibility and large stroke, the 3 finger gripper is suitable for various applications. For example for the CNC – machine loading . Another possibility of application would be assembly. It is also ideal for packaging and palletising.

Request for a quote

WEBER ULTRASONICS AG

Germany

Flange converters are available for all common frequencies (20 to 35 kHz) and power requirements (200 to 5,000 W). They are designed to keep weight at a minimum and their standardized quick disconnect allows for easy and fast integration with robot applications.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber PickRobot stands for the uncompromising automation of slicing applications. Specifically adapted to your application area, it can be used flexibly for all insertion tasks and is available in five different executions: SmartPicker, single, double, triple or quad PickRobot. As powerful and highly efficient automation components with up to 230 picks per minute, the robots integrate perfectly into your line and ensure maximum performance. In combination with the Weber VMAX thermoforming technology, loading portions into an advancing index is possible, which maximizes performance even better than ever before. Advantages Flexible, reduced labor costs, and easy-to-clean Multi-variety and multi-layer packs available for compact spaces (overlapping, 90° rotation, variable portion shapes) Complete filling of the package when portions overlap Virtually eliminates human contact Improves food safety Handles all popular portion shapes and sizes

Request for a quote

BIZLINK ROBOTIC SOLUTIONS GERMANY GMBH

Germany

With LSH Delta we offer an additional product – next to our premium dresspack, the LSH 3. The LSH Delta‘s benefits include: -> Cutting-edge development: A state-of-the-art retract system designed to smoothly and reliably run your operations. -> Seamless integration: The The LSH Delta seamlessly integrates with many robot brands like FANUC, ABB and KUKA. -> User-friendly design: Enjoy the convenience of tool-free and quick opening and closure of the retract system housing, streamlining your maintenance and operational processes. Dresspack maintenance has never been so easy. -> Adjustable flexibility: The LSH Delta’s retract system can be easily adjusted on its base plate using Slide & Click technology – offering you reduced installation time and options to fine-tune in the field. -> Versatility in your spring choice: Different spring forces available. Featherweight system: Crafted with advanced, strong polymer-based material, the LSH Delta is incredibly lightweight at just 4.1 kg.

STÄHLE GMBH

Germany

Robot system for computer driving of cars on test tracks. This configuration combines the actuator of the AUTOPILOT SAP2000 series and the light-weighted and power-saving STEERING ACTUATOR SSP-FF together and used one ruggedized mobile controller unit to run the actuators. As power supply independent batteries are used which can be re-charged from the vehicle DC power it wished and available. Remarkable features of this Autonomous driving system are the build in operational safety features with software watch-dogs, hardware watchdogs and the mechanical safety design with spring-loaded actuator positions and an additional, redundant brake system which stops the vehicle in case of power failure or E-STOP trigger. The robot works as actuator system to an overlaid host automation system and executes scaled actuator commands through its integration interface. Different robot configurations and variants as well as integration interfaces are available.

TRANSFLUID® MASCHINENBAU GMBH

Germany

The right system for every need There is a great variety of handling systems available, dependent on the length of the workpiece. For short tubes there are systems gripping from below with insertion axis and for long tubes there are systems handling from above. Both options can be used in our combination systems. They guarantee ideal access for the operator, so they can complete the setup and any maintenance operations in the best possible way. Transfer stations, turning modules for processing the tube in both directions within an installation and multiple grippers are available for optimized processes. Handling robots from many different manufacturers can also be integrated. The robots are used to move tubes/workpieces. A preassembly of different workpieces is also feasible in this case. The various components can be sorted using sensors and robots.

Request for a quote

SFS GROUP GERMANY GMBH - GESIPA

Germany

Use by industry in robot-controlled applications Both versions of the GAV 8000 can be integrated into robot systems. Industrial robots are used almost everywhere in the production environment. They can be programmed to carry out various movements and can therefore be used highly effi ciently in combination with the GESIPA® rivet equipment. With the controlled, fast and secure production processes it is possible to achieve the following benefi ts by using a fully-automatic GAV combined with a multi-axle robot: • First rate precission • High effi ciency • Short cycle times • High fl exibility

Request for a quote

THOMSON MACHINERY BV

Netherlands

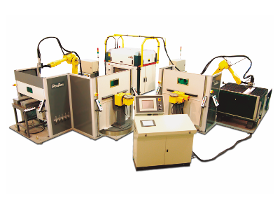

Process Solutions designs, builds, and programs control systems for the efficient and precise operation of industrial robots from industry-leading vendors, including FANUC, ABB, Denso Robotics, Mitsubishi, and Universal Robots. We also provide industrial robot programming and integration services for a wide range of applications, including pick and place, palletizing, packaging, machine tending, and end of arm tooling.

Request for a quote

GRAVOTECH

France

COMPACT DOT PEEN MARKER With 3 sizes available our compact size is the smallest identification marking on the market. This makes the XF150p ideal for restricted spaces and whether on the line or on a robotic arm. The integration is simple in any position, reducing the time and cost of installation. FAST DOT PEEN MARKING When short cycle times are a must, the XF510p dot peen marker is for you, with a marking speed of 12 characters in one second possible, it is setting new standards for speed. TIRELESS PARTS MARKING Able to work on uninterrupted production lines, the XF510p was designed to last. Made with high quality parts we have thousands of units used for aluminum plate engraving, steel engraving, and steel plate engraving worldwide, providing maximum reliability and minimum maintenance costs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives. There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The classic application of industrial robots. The application of wet paint is one of the classic uses of industrial robots. As a specialist for surface coating systems, Rippert naturally offers the full range of solutions in the Ex and non-Ex area. Robots and application technology are integrated into the overall system in relation to the specific customer and his application. Modern software concepts ensure economically optimum operation.

Request for a quote

LVD

Belgium

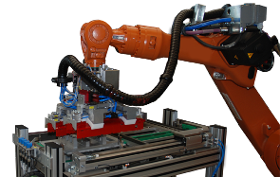

The Dyna-Cell features the high-speed Dyna-Press Pro electric press brake coupled with an industrial robot. The compact, integrated unit automates the bending of small- to medium-sized parts in varying batch sizes at speeds of up to 25 mm per seconds. Dyna-Cell offers maximum bending productivity in a compact footprint of 5 m x 5 m. KEY FEATURES Optimum cost-benefit ratio Fast, electric-drive press brake Lightweight Kuka industrial robot Start final production after <10 minutes CAM and <10 minutes setup Unique gripper that fits all part sizes from 30 mm x 100 mm up to 350 mm x 500 mm Space for two input pallets, two unloading pallets or boxes (Euro pallet size) Intuitive 15” Touch-B touch screen control Fully integrated with LVD's CADMAN® software suite Unmanned or manned operation PERFORMANCE-ENHANCING OPTIONS Easy-Form® Laser system CADMAN-B programming software W-style or universal tooling MODELS

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

The "hand spraying robot" with EJ86 spray head was developed to provide a uniform and reproducible spray pattern in the forging process. It is based on a KUKA robot of the 20 kg class with a specially developed, simplified user interface! With this operating concept, available exclusively from Jerko, time-consuming and expensive robot training at the manufacturer is a thing of the past. Equipped with all necessary interfaces, the robot can be "safely" integrated into new or existing forging lines. Each robot has "Safe Operation" to spray safely even on manually operated presses.

Request for a quote

RUHLAMAT GMBH

Germany

Constant changes in our customers' markets mean that solutions must be quickly implemented. Robot applications by ruhlamat are characterized by extremely rapid handling times compared to the competition. Robots, as the core of automated solutions, offer the advantage of being easily convertible and have a high level of flexibility for the integration of variants and / or new processes. In doing so, ruhlamat integrates all popular robot applications from different manufacturers, depending on the requirements of the customer, or assimilates existing robotics expertise into your production and/or assembly. The application range is endless! Whether as a pure handling device (e.g. extraction cells from injection moulding machines, pick and place) or as the centrepiece of hybrid assembly cells (i.e. work content split between operator and robot): simple convertibility and operational flexibility guarantee the highest possible investment security with high operational...

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc helps our customer to develop the laser welding automation system in Golf clubs manufacturing industry. Integrated with Fanuc robot system and Rofin laser, we provide a total solution for our customer both in laser welding and laser cutting. Industry 4.0 Intelligent manufacturing Full automation production Custom design for automotive industry

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

Welding and cutting processes Depending on material and sheet thickness following processes are used: GMAW - Gas Metal Arc Welding (MIG/MAG) GTAW - Tungsten Inert Gas Welding (TIG), Cold & Hot Wire PAW - Plasma arc welding or cutting FSW - Friction Stir Welding Laser-Hybrid Welding RSW – Resistance Spot Welding igm robots may be used for all non-contact welding and cutting processes. Power sources from many well-known manufacturers can be integrated with our robot systems for welding and cutting applications. Products range from digital inverter power sources for MIG/MAG welding, TIG applications, plasma cutting and welding apparatus to high-capacity devices for the tandem process. Brushing, Grinding and Handling - Manipulation using Robots Through the possibilities afforded by a modular configuration of robot cells and the integration of diverse tools in the robot control sequence, significantly better throughput times and constant process qualities can be achieved. As a...

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

The igm compact systems are optimized for arc welding applications in all mechanical aspects as well as the control hardware and software. In this combination of work piece and robot peripherals, the entire system is kept compact, since the robot changes workstations simply by pivoting the rotary arm or - in other configurations - the work station cahnes is performed by a rotary table. The drive is axis-controlled and provided by an AC servo motor with a special gear box and a built-in digital encoder. The turning fixture is perfect for use as an external robot axis. Work piece movement is completely integrated in the robot control system and permits synchronized movement of the work piece during the welding sequence. The programming takes place simple via the teach pendant K6. All necessary control components for manual and automatic operation are integrated in the system. Examples for igm compact systems and complete welding cells igm compact systems, type RSX 501, 502, 1001,...

Request for a quote

IGM ROBOTERSYSTEME AG

Austria

Robonet: Network operation and remote access ISDES embedded: Weld seam and operating data acquisition system Smartstep: Generating robot programs iPAT: manipulation and the assembling of robot programs i4i: Visualisation of system status Robonet igm software for network operation and remote access from an arbitrary PC to the robot control Transfer of data to one or more machines Remote monitoring of welding and operating data Teach pendant display can be viewed on your notebook or PC ISDES embedded ISDES EMBEDDED is a weld seam and operating data acquisition system for monitoring, documentation and quality assurance of welding processes, as well as for the evaluation of operating data at partially, or fully automated welding robot systems. The ISDES integrated on the control system offers the possibility to record, monitor and evaluate the parameters decisive for the quality as well as the operationally relevant data. isdes embedded functions directly integrated into the...

Request for a quote

ROBOTNIK

Spain

RB-KAIROS+ is a mobile manipulator designed for the plug&play integration of Universal Robots e-Series arms. Its software and hardware are fully prepared to mount the arm OEM DC e-series and thus turn the robotic arm into an autonomous mobile manipulator. This allows unlimited expansion of the cobot workspace and an excellent way to improve the productivity of any factory. It is extremely useful for industrial applications such as pick and place, part feeding, metrology, quality control, operations on large parts or packaging, cleaning, polishing, screwing, drilling, etc.In addition, RB-KAIROS+ has been designed to be a collaborative mobile manipulator able to work in industrial environments. Thanks to its safety laser scanners (optional), the robot can safely share the workspace with the operators. RB-KAIROS+ has a robust steel design and can carry up to 250 Kg. The mobile platform has omnidirectional kinematics based on 4 high-power drive wheels. RB-KAIROS+ is a UR+ certified.

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The 7-axis arc welding robot B4LS from the FD series is compact and, thanks to the integrated cable routing, offers optimal protection during the work process. The extended degree of freedom enables a constant torch orientation when immersing in tight work spaces. In addition, the FD-B4LS offers an extended arm compared to the FD-B4S and thus a larger working radius. Due to the high flexibility, several robots can be positioned closer to each other, so it is possible to have a larger number of robots in the cell or system working together. The most important technical data at a glance: Number of axes: 7 Working Range (P-point): R 2008 mm Max. payload: 4 kg Positional repeatability: +/- 0.08 mm Drive system: AC servo motor Drive power: 5650 W Weight: 321 kg

Request for a quote

OTC DAIHEN EUROPE GMBH

Germany

The new arc welding robot, FD-V8, is equipped for all welding tasks and for load capacities of up to 8 kg. Thanks to integrated cable routing, the FD-V8 can still weld much more interference-free than any other robot in its class. It is 15% faster and the cycle times are accordingly shorter - ideal for maximum productivity. Interference-free: Interference-free welding thanks to integrated cable routing SynchroFeed-ready: Cables for the SynchroFeed / Servo-torch system can be integrated into the robot. Robot distances: Integrated cable routing enables reduced distances between the robots. Increased payload capacity: Higher load capacities of up to 8 kg. Higher performance: Up to 15% higher speeds. The main technical specifications at a glance: Number of axes: 6 Max. payload capacity: 8 kg Working Range (P point): R 1437 mm Positional repeatatbility: +/- 0.08 mm Drive System: AC Servo Motor Drive power: 3016 W Weight: 140 kg

Request for a quoteResults for

Robot integration - Import exportNumber of results

51 ProductsCountries

Company type

Category

- Industrial robots (13)

- Robotics (11)

- Painting robots (8)

- Welding robots (5)

- Automation - systems and equipment (4)

- Assembly robots (2)

- Brakes, servo-brakes and accessories (2)

- Food Industry - Machines & Equipment (2)

- Laser - cutting and welding machines (2)

- Balancing machines and systems (1)

- Food industry packaging machinery (1)

- Industrial cabling (1)

- Marking and labelling machinery (1)

- Marking machines (1)

- Metals - Machines & Equipment (1)

- Palletising machinery (1)

- Paper - Printing - Machines & Equipment (1)

- Pipes and tubes - ferrous metal (1)

- Welding, soldering and brazing - equipment and supplies (1)