- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sputtering targets

Results for

Sputtering targets - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Titanium sputtering targets integrated circuit information storage laser use Metal Fabrication Part

Request for a quote

OPSIL LTD

Bulgaria

We produce targets, both single pieces and complete sets Resistance – as per customer’s specifications

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Chemical Composition: AZO Molding process: CIP+Sintering+Bonding Purity: ≥5.4g/cm3 Density: ≥ 99.95% Application: Widely used in Thin film solar cell electrode film, Low-e glass film Maximum Machining Size L 4000MM T 5MM Straight & Dogbone Customize to Customers' Specification

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Mid-frequency magnetron sputtering technology has gradually become the mainstream of sputtering coating technology. Coating: Multi-function metal coating, composite membrane, transparent conductive coating, Increase return to shoot coating, electromagnetic shielding coating, decorative coating, etc. Power supply: DC magnetron sputtering power supply, MF sputtering power supply, high pressure ion bombard power supply. Target: DC magnetron sputtering target, MF twin targets, planner target, cylinder target. Vacuum chamber structure: Vertical signal door, Vertical double doors. Pump system: Molecule pump (diffusion pump)+Roots pump+ Holding pump(optional: turbo pump, poly cold system) Air system: Mass flow controller (1-4road) Ultimate vacuum: 6x10-4pa (no-loading, clean chamber) Pumping time: No-loading from air to 5x10-3pa<13mins Workplace motion mode: 6 axis/8axis/9axis public and self-rotation

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Ultra high purity tungsten alloy W-Ti sputtering target Plate Planar Billet for Semiconductor Physical Vapor Deposition

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PLANSEE SE

Austria

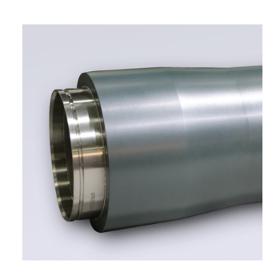

Molybdenum sputtering targets are used for the manufacture of thin-film transistors used in TFT-LCD screens. Targets from Plansee are maximum dense, highly pure and show a homegenous microstructure. Therefore higher sputtering speeds, minimized particle formation during the process and homogenous layers are guaranteed. Available molybdenum alloys: MoTa, MoNb, MoNa, MoW You can choose between our single and multi-piece planar targets. Planar targets are available for all commonly used systems as well as to specific customer needs. Rotary targets are available too.

Request for a quote

PLANSEE SE

Austria

Plansee produces material for wear-resistant coatings, adhesive layers, decorative or DLC coatings. Offering compositions tailored for advanced hard coatings with optimized mechanical and tribological properties. Further topics that might be addressed are: enhancing of thermal and chemical stability, adding of functional properties like self-lubrication, self-hardening and self-healing. To adjust the coating characteristics to the dedicated application, Plansee offers its scientific expertise in alloying of targets and cathodes with elements that influence the coating properties as follows: Grain size and morphology, Hardness adaption, High temperature oxidation resistance, Friction coefficient, Thermal stability, Thermal conductivity, Electrical conductivity, Antibacterial properties, Color effects. Offered sputtering targets and arcing cathodes: Titanium-Aluminum Aluminum-Chromium Chromium Titanium-silicon Titanium Zirconium Tungsten carbide Titanium-diboride

Request for a quote

ANGSTROM SCIENCES, INC.

United States

From sputtering targets to materials used for thermal/e-beam evaporation, Angstrom Sciences has the ability to suggest and direct the most suitable materials for any application. We draw from variety of specialized processing techniques such as Hot Pressing, Cold Pressing, Hot Isostatic Pressing (HIP), Cold Isostatic Pressing (CIP), Vacuum Induction Melting (VIM) and Vacuum Arc Casting to produce homogenous, fine-grained, high-density materials that conform to the strictest application standards. We routinely provide backing plates (copper, molybdenum, copper-chromium) for planar, circular and cylindrical sputtering targets, conductive pastes and thermal transfer foil for sputter target cooling, and also offer bonding services as part of our comprehensive range of services to the PVD community.

Request for a quote

ANGSTROM SCIENCES, INC.

United States

Advances in High Power Impulse Magnetron Sputtering (HIPIMS) or High Impact Power Magnetron Sputtering have long been pursued by modifying power supply systems that can deliver short bursts of power densities to a sputtering target. Angstrom Sciences has developed a series of circular sputtering cathodes capable of sustaining continuous power densities greater than 1500 Watts/in2. Angstrom Sciences’ high power pulsed magnetron sputtering cathodes incorporate two additional cooling channels in the anode body and stem tube to maintain optimum cooling during process operation. The magnetic arrangement within the HPP design is specially optimized for high power, magnetic applications. High Power Pulsed circular magnetrons are directly cooled and available in 4", 6", 8" and 10" outer diameters.

Request for a quoteResults for

Sputtering targets - Import exportNumber of results

10 ProductsCountries

Company type