- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- system tanks

Results for

System tanks - Import export

POMPES JAPY

France

Continuous management system for the tank's level. OCIO reports the static pressure created by the height of the liquid via a tube inserted in the tank, and displays the level or volume of the liquid.

Request for a quote

WESPY INDUSTRIAL PARTS WASHING MACHINES

Turkey

The particulate filter cleaning machine is designed to clean the particulate filters of both passenger cars and commercial vehicles. The machine is completely made of stainless steel. With the water purification system, water in the tank is recirculated and cleans the inside of the particle filter.The machine starts the washing process by measuring the clogging rate of the filter after test button on the touch-operated display is selected. After the washing process is completed, you can test again and measure that the filter is cleaned. Then you can finish the washing process and proceed to the drying process. After drying the inside of the filter, the cleaning process is fully completed. There are bag and cartridge filters on the machine. Tank has heat insulation. The machine has lighting and a steam discharge fan. You can wash and dry 2 different filters simultaneously, as the machine has individual washing and drying processes.The machine exist in manuel and pneumatic.

Request for a quote

FERPLAST SNC

Italy

CONTAINMENT TANKS WITH PERCH FOR 1000 LITERS IBCS Containment tanks with perch to facilitate emptying, specific for 1000 liter cisterns. They are available for the storage of 1 or 2 small tanks. The containers of polluting liquids must be stored in a safe manner, in order to prevent contamination of the aquifers in particular. The collection tanks are watertight, oven-painted with epoxy powders and equipped with a hot-galvanized, removable grid. Color RAL 5010 blue. They are also equipped with special seats for forklift loading. Available models: FPB826C: tank for the storage of 1 1000 liter cisterns FPB8070T: tank for the storage of 2 1000 liter cisterns It is the responsibility of the user to check that the products destined to be stored and handled are compatible with the construction material and the possible painting of the tanks.

Request for a quote

FERPLAST SNC

Italy

METALLIC CONTAINMENT TANKS FOR 1000 LITERS IBCS Containment tanks, specific for 1000 liter cisterns. They are available for the storage of 1 or 2 cisterns. The containers of polluting liquids must be stored in a safe manner, in order to prevent contamination of the aquifers in particular. The collection tanks are watertight, painted with epoxy powders and the support surface is in hot galvanized grating and can be removed. Blue RAL 5010 color. The tanks are equipped with special seats for forklifting. Available models: FPB826S: tank for the storage of 1 1000 liter cistern FPB8070C: tank for the storage of 2 1000 liter cisterns It is the responsibility of the user to check that the products destined to be stored and handled are compatible with the construction material and any painting of the tanks.

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

The ViscoMT-XS hobbock emptying system offers a modern way of emptying containers.The following advantages result from the use of eccentric screw pumps for the removal of the medium: - container sizes from approx. 5 l to 50 l - viscosities of approx. 80,000 - 2,000,000 mPas - very low shear stress of the medium - very low pressure load of the medium (max. 18 bar) - Removal of media loaded with fillers - no backflow within the sampling pump - electrical control of the pump with pressure control - valve-free pump system - no material pressure reducer necessary due to electronic pressure adjustment - very good residual emptying (less than 1% residue) - electronic "empty" and "almost empty" message Application: - Removal of media directly from the delivery container, e.g. silicones, adhesives, resins, greases, colour pastes, metal-filled pastes (Cu and Ni solder pastes, Al and Ag pastes) - supply of media to dispensers - direct dosing as pulsation-free flow rate

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR MUNICIPAL WASTE WATER TREATMENT Lipp has for many decades been an established partner of municipal waste water treatment plants, engineers and general contractors in the field of tank and system solutions for municipal waste water treatment. Due to their method of construction as well as flexibility in the choice of materials and ideal diameter – height ratios, Lipp tank and system solutions are especially suitable for the needs of small to large sewage treatment plants. They are ideally tailored to one another, but may also be embedded as individual island solutions into existing systems and are therefore equally popular with planners and end users alike. The stainless steels used and the double seaming guarantee maximum water tightness and durability with low maintenance for a wide variety of waste waters, slurries, process liquids and gases. The versatility in terms of the system solutions offered for municipal waste water treatment plants

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TANKS AND SYSTEM SOLUTIONS FOR SOLID, LIQUID AND GASEOUS SUBSTANCES As a tank construction specialist, we offer quality tanks and system solutions in steel for industry, communities and agriculture. Our unique Lipp System construction method ensures the highest levels of quality when storing solid, liquid and gaseous substances. Your project, from an individual tank to a complete turnkey plant, will be completed with the emphasis firmly on longevity, flexibility and individual adaptability. With over 55 years experience in plant and tank construction, LIPP GmbH is a family company which is active worldwide. We have carried out over 10,000 projects world wide and own over 170 pioneering patents.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

INDIVIDUAL SERVICE FOR EVERY CUSTOMER After installation of a Lipp tank system, the primary concern is safeguarding the market leading performance of all the associated parts. This process begins from the very first consultation – as Lipp produces efficiency estimates and process diagrams as a comparison point. Lipp understands the particulars of every system that it installs, helping to bring a personalised service and a one stop shop to every customer

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP welded tanks are erected using the LIPP Welding Technology, a unique method of construction enabled by a custom automated rig designed and manufactured by LIPP. This procedure can claim a number of advantages over other traditional welding methods. Firstly, the unique steel profile increases stability and so reduces material costs at the same time. Secondly, the automated endless tape process continually welds layers below in a rotational cycle and reduces the number of on site workers. LIPP Welding Technology enables welding both black steel and stainless steel of different grades, allowing numerous applications. LIPP aims to increase construction efficiency through the implementation of unique techniques and technology, ultimately benefiting customers via a cost effective system. The key facets for the construction of a LIPP storage system are automation, continuously variable tank dimensions, reduced space requirements for onsite construction and increased worker safety.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

HIGH QUALITY AND SAFETY STANDARDS LIPP brings over 55 years of experience in the field to every project, helping to meet the most demanding safety and quality standards that will deliver profitability and reliability. Proven technologies, such as the spiral LIPP Double Seam System and Verinox material, have been developed and proven to deliver both flexible and efficient storage systems. Tanks are erected via a construction method exclusively employed and developed by LIPP, delivering customizable tanks for any application with a volume of 10,000m3 or more. Perfectly matched to the purpose of each installation, each tank incorporates large volume with a customized interior. LIPP understands that adaptability provides solutions for various applications and requirements – so customers can even specify their own services to lower the total cost of investment.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

With such flexibility, the sales team at Lipp can enable any customer to specify exactly what is needed for their installation. From complete, turnkey systems to individual components and accessories – Lipp can support customers whatever their requirements. Consultation is a primary objective for Lipp before any work is undertaken. Lipp provides diagnostic tests, efficiency calculators and flow sheets to visualise a tank system and inform the customer of the performance they can expect. This is especially useful for anaerobic digestion – where Lipp experience supports the efficiency and safety of the system from design through to construction. Particular attention is always paid to the content to be stored within the storage system, which allows Lipp to offer customers the chemically stable materials and accessories to get the most from their storage tanks and digesters. Fundamentally, Lipp’s focus on the customer allows consultation and sales to be perfectly integrated

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TAILOR MADE SOLUTIONS As a family owned company that offers a unique tank storage system to customers across the world, Lipp knows the high value of effective communication and customer support. Whether consulting with a Lipp specialist on a tank system design or ordering extra accessories for an installed system, the same professional help and guidance is always available. Lipp focuses on providing the optimum solution for the user, entirely customisable and ultimately efficient. Lipp will always recommend solutions that will increase the performance of a tank system while also ensuring – that it is the most suitable solution for the customer.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

Lipp tank and system solutions for municipal waste water treatment have been realised in close cooperation with well known design companies and end customers since the 1980s. In addition to municipal waste water treatment plants in Germany, Austria, Switzerland, France and other European countries, the Lipp system has already been successfully installed in many Asiatic projects. Lipp waste water tanks are offered in variable sizes and with individually adapted features (material, covers, additional equipment). Our success lies in professional management and close cooperation with all stakeholders over the entire project period. Reliable tank solutions, timely installation and numerous reference plants both in Germany and worldwide make Lipp an important partner in municipal waste water treatment.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

CONTAINER AND SYSTEM SOLUTIONS FOR THE INTERMEDIATE STORAGE OF HEAT FROM WASTE HEAT OR RENEWABLE ENERGIES The intermediate storage of heat from biogas plants, biomass cogeneration plants or other heat sources is an important prerequisite for effective use. Lipp buffer tank systems are economic system solutions for the storage and supply of thermal energy and can be easily integrated into customised solutions for local heat supply. LIPP BUFFER STORAGE TANKS The individually tailored solution appropriate to heat storage requirements with useful volumes of 80 to 3,000 m³ is made of stainless steel with the Lipp dual seam system and operated in conjunction with insulation adjusted to the application at about 95 ° C. Since the Lipp system is unpressurised, the container solutions are extremely low maintenance and are very durable. The high volume, above ground Lipp storage tanks have been specially developed for this application and are popular with end users and energy suppliers alike.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

SYSTEM SOLUTIONS FOR PROCESS WATER In the area of process fluids, the Lipp system offers many advantages due to its high flexibility in terms of tank dimensions and choice of materials. This means that tank solutions can be individually tailored to the process and the media to be processed. The method of installation, largely without cranes or scaffolding, and even inside buildings if necessary, make Lipp tanks and system solutions an attractive option for engineers and end users alike. As in other areas, Lipp convinces above all by its high flexibility and easy integration into planned or ongoing investments. A timely and high quality design and professional project and document management are a matter of course for Lipp.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

TANK AND SYSTEM SOLUTIONS FOR WASTE WATER TREATMENT PLANTS Individual, customised container and system solutions have been one of the core business areas of Lipp GmbH for decades. This is demonstrated by the long list of references for completed tanks and equipment that have been implemented in close cooperation with well known engineering firms and companies for industrial waste water treatment plants at home and abroad. From simple, open topped waste water tanks through process vessels with special requirements for stainless steel and sealing materials to fully equipped fermenter types, (SBR, CSTR etc.) for different applications, Lipp offers a wide range of system solutions. Each project is planned and manufactured individually according to specific customer requirements for material, diameter, process instructions etc., and installed and tested if necessary in close cooperation with the partners. The versatility of the Lipp system in combination with process

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

WASTE TO ENERGY INDUSTRY BIOGAS FROM ANAEROBIC WASTE WATER TREATMENT AND WASTE FERMENTATION PLANTS. Due to their technical characteristics and profitability, Lipp tank and system solutions are used in a variety of industrial biogas plants. Two areas of application can be distinguished, which in many cases also follow both objectives. APPROPRIATE PROCESS TECHNOLOGY, SUITABLE CONTAINER TECHNOLOGY AND THE RIGHT DIMENSIONSFirst, the anaerobic treatment of various industrial waste waters, such as in food production, biofuels or similar. The main objective here is the anaerobic pretreatment of highly contaminated but easily degradable waste water to reduce the COD load before it can go to the next stage of aerobic waste water treatment. The challenge is that in spite of the low DM content, a high degree of degradation is achieved by biomass retention or return and at the same time, biogas is produced. Due to the flexibility and variability of the Lipp system in terms of procedures

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

LIPP drinking water tanks for water supply companies are offered together with our project partner Kurz Leitungsbau GmbH. In doing so, we meet the highest standards applicable to the supply of drinking water, from planning and conception up to construction. Our automated welding process for high alloy stainless steels based on the LIPP System enables us to offer tanks with a maximum volume of 10,000 m3. In addition, on site production “off the production line” enables construction to be completed within the shortest possible time. Optimum quality thanks to automated welding process Material savings and additional stability thanks to circumferential profile Short construction times thanks to mechanised production Easy to maintain and clean Low investment and maintenance costs Can be set up indoors or in the open air Turnkey complete solution or components

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

HIGH QUALITY TANKS AND SYSTEM SOLUTIONS FOR MORE THAN 50 YEARS

Request for a quote

GHM MESSTECHNIK GMBH

Germany

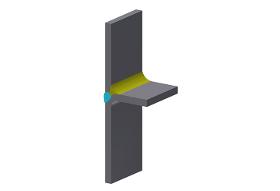

Hygienic thread EHEDG-certified seal system On hygienic seal systems For tanks, containers and pipelines

Request for a quote

GHM MESSTECHNIK GMBH

Germany

Hygienic thread EHEDG-certified seal system On hygienic seal systems For tanks, containers and pipelines

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Coating of pipings and air ducts, firing, boiler and heating systems, tanks, exhaust systems, silencers, light-metal bodies on utility vehicles Repairs to mechanically (stone impact) or chemically (de-icing salt) damaged aluminium rims Shielding of non-metallic materials, e.g. cardboard, wood, glass or plastics etc. Advantages and benefits Excellently suited for sole, decorative corrosion protection Universal protective and decorative coating for all materials Economical due to low consumption and self-cleaning spray valve High covering capacity Fast-drying

Request for a quote

RUDOLF GUTBROD GMBH

Germany

The fluoropolymer coating for special tank systems and containers. Modern tank and environmental technology requires safety and cost effectiveness. Gutbrod stands for innovative ideas and a dedication to service in coating with fluoropolymers and other technical, high-performance materials. Using products with the name, a chemical and acid resistant inner coating that is sustainable and cost-effective can be applied to special tank systems and containers through an access port. The material for this Fluorpolymer-coating, which will be applied with a specific method, is highly resistant against chemicals and acids, and has extraordinarily advantages, compared with common coating and lining systems.

Request for a quote

FERPLAST SNC

Italy

Ideal for safely storing gas tanks. Welding system certified UNI EN ISO 3834-2. The tank is equipped with: Hinged door with anti-intrusion closure Galvanised roof Tanks inner hooking in chequer plate steel Modular structure Ramp access in sheet metal Safety labelling

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

With a diameter of 2.5 m and a height of 3 m, the tank and separator system is equipped to reliably drain wastewater for a small city of up to 18,600 residents. In addition, the tank offers a gas and odor-tight seal. Three pumps provide good operational reliability; maintenance work is easy to complete thanks to dry installation. Draining towns with up to about 18,600 residents which cannot be drained using natural gradient or as an intermediate pumping station within the context of a pressure drainage system Residential and industrial areas Towns Communities Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One holding tank with three separator systems Three centrifugal pumps and motors according to type and operating location required Six pump gate valves Three STRATE non-return valves One Y-pipe DN 250 Three pressure pipe gate valves DN 250 Level measurement

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

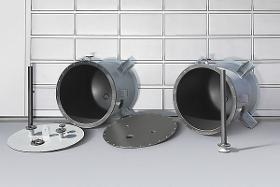

The AWALIFT 1/2 is used primarily in municipal applications for draining large properties. It is a fully automated, floodable sewage pumping system with a proven separator system for up to 750 EW. Alternating two pumps provides a high level of operational reliability. There is no need to provide reserve pumps. This system also has a gas and odor-tight tank, the surface of which is coated with high-quality corrosion protection. •Larger buildings, industrial companies, individual streets •Facilities that cannot be drained using natural gradient •As protection from backwater damage •Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One tank with two separator systems Two rotary pumps and motors according to type and operating location required Two non-return valves AWASTOP DN 100 K Y-pipe DN 100 Two pressure pipe gate valves DN 100 Level measurement LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 0/2 double installation with proven STRATE system conforms to the requirements of DIN 1986-100 and DIN EN 12056-4. The installation forms a closed, gas and odor-tight system that fulfills the highest requirements for hygiene and safety. The system can also be installed directly in the basement; no excavation is required. If it is installed outdoors, however, using a STRATE AWALIFT shaft is recommended. Larger buildings, industrial companies, individual streets Where the reserve pump has to guarantee fail-safe operation e.g. in restaurants and public buildings Facilities that cannot be drained using natural gradient As protection from backwater damage Infrastructure facilities such as airports, industrial parks, subway systems etc. Product features One tank with two separator systems Two centrifugal pumps and motors according to type and operating location required Two non-return valves AWASTOP DN 100 K Two pressure pipe gate valves DN 100

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The AWALIFT 0/1 requires a space of just 1200 mm x 1200 mm or d=1500 mm. Thanks to its unique design, it can be installed in even non-standard installation areas. A variety of available motor power levels make it suitable for use in a wide range of applications. Multi-family homes Facilities that cannot be drained using natural gradient As protection from backwater damage Product features One tank with separator system One centrifugal pump and motor according to type and operating location required One non-return valve AWASTOP DN 100 K Level measurement Pump control type AWAmaster 1 1.5 m power supply cable, with CEE plug LGA certified according to DIN EN 12050-1 /. -4

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The STRATE AWALIFT 74/1 is used primarily for draining floors, multi-family buildings and properties above the backflow level in accordance with DIN 1986-100, e.g. for properties that cannot be drained via a natural slope. DIN EN12056-4 establishes the upper edge of the street at the connection point to the public sewer system as the backflow level. Two-family homes Facilities that cannot be drained using natural gradient As protection from backwater damage Product features One tank with separator system One centrifugal pump and motor according to type and operating location required One non-return valve AWASTOP DN 100 K Level measurement Pump control type AWAmaster 1 1.5 m power supply cable, with CEE plug LGA certified according to DIN EN 12050-1 /. -4

Request for a quoteResults for

System tanks - Import exportNumber of results

128 ProductsCountries

Company type

Category

- Tanks, metal (25)

- Pumps (7)

- Water - production and distribution (7)

- Applicators for adhesives and glues (3)

- Catering - machinery and equipment (3)

- Cleaning machines, industrial (3)

- Food industry - machinery and equipment (3)

- Storage tanks (3)

- Adjustment - machine tools (2)

- Cleaning, industrial (2)

- Cleaning, tanks and cisterns (2)

- High-pressure cleaning machines (2)

- Hoses, pipes and tubes - plastic (2)

- Industrial containers (2)

- Kitchens - furnishing (2)

- Measurement and regulation equipment and instruments - pressure (2)

- Optical fibres (2)

- Agricultural systems and equipment (1)

- Autogenous welding machines (1)

- Cheese-making machinery (1)