- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cylinders- hydraulic

Results for

Cylinders- hydraulic - Import export

1ST MACHINE TOOL ACCESSORIES

United Kingdom

High speed operation Large through bore Kitagawa hydrualic cylinders are made with high grade alloy steel. The F series cylinders are Kitagawa's high speed open centre with the largest kitagawa sizes. The cylinder can be bought as a single unit or to suit a required machine under request.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast knows heavy trucks. We cut our teeth building hydraulic cylinders for heavy trucks all the way back in 1993. Hydraulic cylinders on trucks are subjected to all forms of contamination that would destroy a poorly designed cylinder. Dirt, grit, rain, salt, tar, chemicals, solvents and cleaning agents all combine to attack the cylinder and its seals. Despite all this, the cylinders are still expected to perform. Cylinder failure means downtime, employee overtime, loss of vehicle availability, less productivity and reduced profit. Gidrolast cylinders are built tough to meet these conditions. They can be found mounted on garbage trucks, dump trucks, belly dumpers, semi end dumpers, boom trucks, knuckle boom loaders, road pavers, concrete mixers, concrete pumps, mobile cranes, tilt beds and tow trucks. Applications include dump cylinders, aerial boom cylinders, compaction cylinders, outrigger cylinders, tilt cylinders, swing cylinders, plough lift cylinders, and more.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

From the sticky tar sands of Uzbekistan and the frozen windswept wastelands of Ural to arid, sun -leached Texas and the sizzling hot deserts of Saudi Arabia; from the warmth of the Caspian sea to the cold salt spray of the ocean, Gidrolast hydraulic cylinders are the actuators of choice in the gruelling oil field industry, both onshore and offshore. Oil rigs are located in some of the most demanding locations in the world. Blowing sand, sticky tar, extremes of hot and cold temperatures, corrosive elements and heavy-duty use. The cylinders used are often large-bore and long-stroke. Downtime is measured in millions of dollars. In addition to all that, the equipment is often located in remote areas far from civilization. Rugged, reliable cylinders are a must. Gidrolast designs and builds heavy-duty hydraulic cylinders, both rod style and telescopic, to withstand the tough conditions and demanding requirements of the petroleum industry.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast specialises in the design and manufacture of both Single Acting and Double Acting Telescopic Hydraulic Cylinders. We build both standard catalogue telescopic designs as well as custom application engineered telescopic cylinders. Often a hydraulic cylinder is required to fit into a very tight space and yet provide a stroke that is actually longer than its fully retracted length. A standard rod cylinder cannot do this. A telescopic cylinder, however, can achieve a very long stroke from a compact retracted length. Telescopic cylinders use a series of nested tubular segments sliding within one another (see diagram below). This enables them to provide a very long output stroke from a very short retracted length in one combined actuator. These cylinders are available in 2, 3, 4, 5, or even 6 stages. Most telescoping cylinders are single acting. That means that they extend using hydraulic pressure but then retract using gravity and the mass of the load.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Mining equipment is continually subjected to tortuous conditions that punish hydraulic cylinders. These gruelling conditions include dust, grit, heat, cold and moisture. In addition, the equipment is subject to slamming loads and mechanical impacts. Gidrolast designs and manufactures heavy-duty hydraulic cylinders that endure these very difficult conditions. Gidrolast cylinders can be found on hydraulic equipment in surface and sub-surface mining operations all around the globe. They are installed on dredgers, hydraulic shovels, dump trucks, oversized off-road equipment, tunnel boring machines, ore haulers, ore crushers and aggregate conveyors, to name but a few. We manufacture both rod cylinders and telescopic cylinders, double and single action, in sizes from 12mm (1/2″) up to 700mm (28″) bore. Call us to find out why mining equipment OEM’s around the world depend on Gidrolast cylinders.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GIDROLAST CO., LTD

United Kingdom

Fork lift trucks, pallet loaders, conveyors, cranes, and so on. These machines are at the heart of any facility moving materials and products. These machines also depend on the power of hydraulic cylinders to do their work. That means that the cylinders have to be reliable. A failure means loss of production and profit. At Gidrolast, we appreciate that. We build our cylinders to last with precision machining and using heavy-duty seals and bearings. Our factory uses the latest high-technology production methods including robotic welders, friction welders and skive roller burnishing. Our quality control methods are the best in the business. And to cap it off, all of our cylinders are 100% pressure tested before they leave our factory. That means that our customers are 100% confident when they mount a Gidrolast mast cylinder into the bowels of their fork lift truck or assemble a lift cylinder under a heavy-duty conveyor.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Metallurgical equipment all endure heavy-duty service under very demanding environmental conditions. Equipment is subjected to moisture, dirt, saw dust, wood chips, sap and tar and slamming loads. The hydraulic cylinders used on that equipment must meet these challenges day after day. Gidrolast has over 15 decades of experience building hydraulic cylinders for this tough industry. In fact, you could say we cut our teeth in the forestry industry. For our customers, that experience is invaluable. Gidrolast designs cylinders that are able to endure the difficult conditions that metallurgical machinery encounters on a daily basis.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

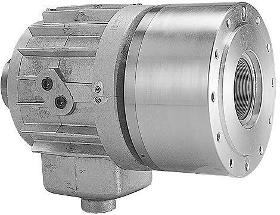

Kitagawa's SR series is a open centre hydraulic cylinder to match Kitagawa's B200 and BB200 range.

Request for a quote

1ST MACHINE TOOL ACCESSORIES

United Kingdom

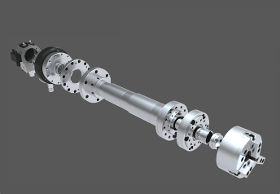

For example- Full System Chuck Adaptor Threaded Connector Drawtube Cylinder Adaptor Hydraulic Rotating Cylinder Anti Rotation Bracket Drain, Hoses and Fittings Part systems can be either: Front End- Chuck Adaptor Threaded Connector Drawtube Rear End: Drawtube Cylinder Adaptor Hydraulic Rotating Cylinder Anti Rotation Bracket Drain, Hoses and Fittings Or indeed any part(s) there of.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Military and Naval equipment has some of the most demanding specifications and requirements of any machinery. It has to. Lives depend on it. From the frozen arctic tundra to hot humid jungles, from arid sand-blown deserts to the windswept salt spray of the oceans, military equipment is exposed to every conceivable environment on the planet. Military hardware is often stored unused for months or years at a time, but then must be ready to move and operate at a moment’s notice. The hydraulic cylinders used in this equipment must be of the very best quality. Gidrolast makes them. Gidrolast cylinders are carefully designed and engineered, using only the finest construction materials, and are precision-manufactured with cutting edge industrial equipment. The result is cylinders that meet the toughest military and naval specifications.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Hydraulic cylinders used on shipboard machinery or in shipyards must endure the toughest of conditions, including hot and cold temperature extremes, exposure to salt water, driving rain, ice, as well as dirt and many other forms of contamination. That is an extremely abusive environment for hydraulic actuators. Cylinders used under these conditions must be designed and manufactured with these well in mind if they are to survive and work reliably. In addition, many hydraulic cylinders used on ships and harbour cranes are very large-bore and very long-stroke. Their large size makes frequent repair or replacement simply out of the question. Other marine cylinders are mounted in a ship’s machinery that is very difficult to reach. All these factors makes reliability a primary concern for marine cylinders. Gidrolast has a great deal of experience in building marine-grade hydraulic cylinders that thrive under those trying conditions.

Request for a quoteResults for

Cylinders- hydraulic - Import exportNumber of results

12 ProductsCountries

Company type

Category