- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- part cleaning

Results for

Part cleaning - Import export

SAMSYS GMBH

Germany

With the MiJET part cleaning system it is possible to keep workplaces clean and workpieces hygienically cleaned with the simplest technology. An electrical connection is not necessary. Only a compressed air connection is required to use the device. Application The actual task of the MiJET is to filter oily air. Chips of the work pieces accumulate in the container. Operators often tend to blow off finished workpieces into the machine. This quickly results in dirty working environments and poor air in the production hall. However, we avoid this by exhausting these fumes. Oils are trapped from the exhaust air and chips and coolants accumulate in the container.

Request for a quote

SAMSYS GMBH

Germany

With the MiJET part cleaning system it is possible to keep workplaces clean and workpieces hygienically cleaned with the simplest technology. An electrical connection is not necessary. Only a compressed air connection is required to use the device. Application The actual task of the MiJET is to filter oily air. Chips of the work pieces accumulate in the container. Operators often tend to blow off finished workpieces into the machine. This quickly results in dirty working environments and poor air in the production hall. However, we avoid this by exhausting these fumes. Oils are trapped from the exhaust air and chips and coolants accumulate in the container.

Request for a quote

SAMSYS GMBH

Germany

Customized MiJET AC filter for model 30.5 cm Suitable for MiJET 30.5 cm and washing station with MiJET 30.5 cm We have developed the MiJET filter to be able to use it in addition to the oil mist filter. The activated carbon filter is put over the existing air filter. It is fastened with three locking hooks. These keep the active carbon filter in position. The activated carbon filter cannot be used individually. The AC filter helps the user to filter aerosols from the exhaust air. These are increasingly produced by the use of cleaning solutions. MiJET products can be purchased via our Shop.

Request for a quote

SAMSYS GMBH

Germany

Custom MiJET activated carbon filter for model 20.3 cm Suitable for MiJET 20.3 cm and washing station with MiJET 20.3 cm We have developed the MiJET filter to be able to use it in addition to the oil mist filter. The activated carbon filter is put over the existing air filter. It is fastened with three locking hooks. These keep the ACF in position. This Filter cannot be used individually. The AC filter helps the user to filter aerosols from the exhaust air. These are increasingly produced by the use of cleaning solutions. MiJET products can be purchased via our Shop.

Request for a quote

SAMSYS GMBH

Germany

he cleaning station MiJET Wash Station with integrated cleaning basin ensures clean workplaces and oil-free cleaned workpieces. No electrical connection is required for this. Only a compressed air connection is required. Application The washing station consists of a worktable, in which a wash basin with nozzle and a MiJET are installed. The washbasin serves as a pre-cleaning unit, the MiJET then removes excess cleaning agent from the workpieces. Ideally, the washing station is useful for heavily oiled workpieces as well as for scratch-sensitive parts. The advantage for easy blowing off of the parts is that oil mist formation is prevented and thus the health of the operator is not endangered. In addition, the working environment remains free of oil.

Request for a quote

SAMSYS GMBH

Germany

The cleaning station MiJET Wash Station with integrated cleaning basin ensures clean workplaces and oil-free cleaned workpieces. No electrical connection is required for this. Only a compressed air connection is required. Application The washing station consists of a worktable, in which a wash basin with nozzle and a MiJET are installed. The washbasin serves as a pre-cleaning unit, the MiJET then removes excess cleaning agents from the workpieces. Ideally, the washing station is useful for heavily oiled workpieces as well as for scratch-sensitive parts. The advantage for easy blowing off of the parts is that oil mist formation is prevented and thus the health of the operator is not endangered. In addition, the working environment remains free of oil.

Request for a quote

PERO AG

Germany

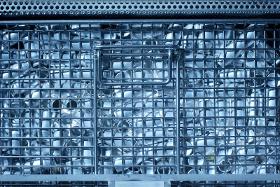

The ROTIMAT 3U is a universal machine for the cleaning of a wide range of parts. It guarantees maximum technical cleanliness, irrespective of the degree of contamination of the parts. It is equipped with two baths for cleaning, and subsequent iron phosphatising/rinsing, wherby each bath has its own pump cycle. The ROTIMAT 3U can be operated with standard baskets or customised parts carriers. Cleaning with aqueous media (acidic, neutral or alkaline) 660 x 480 x 300 mm 4 x 480 x 320 x 200 mm Spray cleaning for extra demanding applications Catering for wide range of parts Suitable for any cleanliness level from light dirt removal to high technical cleanliness Available as 2bath unit with loading of the unit via Manual loading table Manual charging unit Automatic charging unit

Request for a quote

PERO AG

Germany

After cleaning, parts are normally dried. Efficient drying keeps cleaning medium consumption low, and thus helps protect the environment. In addition, drying effectively prevents recontamination and corrosion. When drying tightly packed or porous parts, drying at atmospheric pressure might not be effective, so that drying under vacuum is the only option.

Request for a quote

PERO AG

Germany

The parts are immersed in the wet medium. Dirt is dissolved from the surface by the heated wet medium. By moving the parts while immersed, cleaning is assisted by a mechanical effect. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The wet medium is sprayed through nozzles onto the surfaces of the parts. Particles are removed from the parts by kinetic energy, and then washed away. The cleaning result is primarily determined by the position and shape of the nozzles, the spray pressure and the volume of media applied to the parts. In industrial parts cleaning, the surfaces are then normally rinsed and dried.

Request for a quote

PERO AG

Germany

The R0 has been specifically designed for intermediate and final cleaning of small and extra small parts. Thanks to its universal process technology, the R0 offers operators unrivalled cleaning performance in an extra compact machine. The R0 can be transported through door clearances of as little as 1,000 x 2,000 mm. Depending on the model, the cleaning unit can be loaded from the long or from the short side. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; halogenated hydrocarbons; other solvents on request Available as UNIVERSAL unit Top quality cleaning in compact unit Short cycle times High throughput Available as 1 and 2bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile on floor or in the pit, mounted on a trolley. Grey reinforced fibre glass collector with automatic dirt water recycling incl. drip-off grid with slosh bafflet. Load capacity 80l

Request for a quote

PH-CLEANTEC GMBH

Germany

Mobile on floor or in the pit, mounted on a trolley. Grey reinforced fibre glass collector with drip-off grid without recycling unit. Load capacity 80l

Request for a quote

JONAS WERKZEUGBAU STANZEREI GMBH

Germany

A professional, payable cleaning and defatting we offer for specially produced Stamping parts Drawing parts Extruded components Turned parts Milled parts Products from electrical engineering and fine mechanics Parts from (electric) motor production Heat exchanging devices An optimal cleanliness of the elements has found its way to become an important quality characteristic. By our professional procedure of cleaning parts your stamping parts will be optimally defatted and residue-free dried. We are sure, that you will love the clean final products. Our cleaning plant is an up-to-date version and works in vacuo with DOWCLENE 1601 (based on modifies alcohol). The pros lower toxicity residue-free drying, non-detergent

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Doubly well-rounded: The Skinner ASP 560 D is an open derinding and defatting machine for round cuts, such as ham, shoulder and haunch. Advantages Clean and fast removal of rind and simultaneous removalof shoulder fat Perfect collection of rind and fat Variable adjustment of the rind and cutting thicknessfor fat removal Two workflows in one machine Toolless removal and assembly of all parts to be cleaned Modern, hygienic design Ergonomic machine design Integrated crate shelf Space-saving Options: Application-specific table for ham/shoulder without bone Extended discharge table Special tension rollers

Request for a quote

VISCOTEC PUMPEN- U. DOSIERTECHNIK GMBH

Germany

ViscoTec 1C dispenser vipro-PUMP ▪ Volumetric dispensing, regardless of viscosity ▪ For low to high viscosity materials ▪ Particularly suitable for highly abrasive, filled or shear sensitive materials ▪ Modular scalability of volume flow within the model range ▪ Programmable suck-back prevents dripping or stringing of product ▪ Material entry with Tri-Clamp DN 20 connection for optimized material flow and fast coupling of material supply ▪ Locking ring for easy and fast disassembling of drive unit ▪ Drive unit connection with optimized power transmission free from clearance ▪ Optimized dispenser bracket for easy adjustable mounting ▪ Long lifetime due to low wear ▪ Different rotor and stator materials available ▪ Continuous dosing, pulsation free ▪ Interior non-stick coated ▪ Dividable rotor assembly for easy & fast replacement and low spare part costs ▪ Easy cleaning and maintenance due to quick assembly and disassembly options

Request for a quote

PACA GMBH

Germany

The Paca Component Cleaner is a professional, fast cleaner. Versatile and effective, it is universally usable and largely biodegradable. It removes oil and grease, hardened residues and brake fluid. It degreases glued surfaces and sealing surfaces, cleans com- ponents efficiently and safely, dries quickly and leaves no residue. CO2 propellant AOX-free Fields of application The automotive industry, construction machinery, agricultural machinery, tools, sport, hobbies, home and garden, office Usage Check the rubber and plastic parts for compatibility beforehand, as Paca Component Cleaner may cause lacquers to corrode. Spray Paca Component Cleaner at close range onto the part which needs cleaning, repeating this step if there is excessive contamination. Allow the solution to dry, then wipe over with a clean cloth. Always shake Component Cleaner well before use! Batch quantity/Packaging units Batch quantity: 150ml and 500ml spray cans Packaging units: 24 150ml cans or 12 500ml...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUX-GERÄTE GMBH

Germany

Pre-assembled pump kit for food and pharma. The pump-kit is ideal for hygienic applications and suitable for conveying media out of drums, IBCs and other containers. It can be easily and quickly disassembled for cleaning / sterilization and can be completely stripped down to individual parts. Comprising drum pump FP 427 FOOD, outer tube stainless steel 1000 or 1200 mm, commutator motor F 458, hose, hand nozzle, hose connection and compression gland. Product attributes: - Sealless in the liquid area - Minimal dead spots - Can be taken apart completely in only a few steps - Disassembly almost without tools possible Benefits: - Ideal as hygienic pump - Can be quickly and easily taken apart for cleaning - All parts in contact with the medium can be sterilized - Transfers also fluids containing solids such as juices with pulp or soups with spices - Appropriate for food contact acc. to EC 1935/2004 and FDA CFR 21 - Also available for the ex-area with drum pump FP 430 Ex FOOD

Request for a quotePWL GMBH & CO. ANLAGENTECHNIK KG

Germany

Application An efficient and reliable fine sieving is essential not only for a comprehensive water recycling but for completely closed water circulations. For these applications, the Drum Filter MDF with mesh sizes between 25 and 2000 µm is the best choice. This filter offers a high capture rate at low operational costs during continuous operation. The choice between different cleaning media is part of the adjustment to the individual site conditions. In addition, different discharge devices and the level controlled drum rotation have to be considered. Function The Drum Filter MDF is a unit made of stainless steel, designed for liquid/solid separation within the field of process and waste water of various industries. From the Drum Filter’s inlet connection the waste water runs off into the filter drum consisting of a steel construction which is covered with a stainless steel wire gauze. The solids settle at the gauze and are transported upwards by the rotating filter drum. The...

GEPPERT RÜHRTECHNIK GMBH

Germany

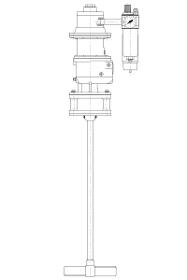

GLP - Peumatic top-entry agitator The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

GRP - Pneumatic agitator GRP – pneumatic agitator The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. ((Infotexte)) Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0. The GRP is a pneumatic agitator...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GLP is a pneumatic top-entry series agitator that is used for homogenizing, dispersing, emulsifying and suspending in vessels and for viscosities up to 500 mPas for instance in wastewater treatment, chemical and cosmetics as well as in food industries. The agitator speed adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight. Power transmission via elastic coupling in the bearing housing. The agitator shaft has a double bearing in an aluminum housing separated from the drive. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air, expanding in the air engine cools the agitator drive. Includes filters, pressure reducers with pressure gauge that indicates the secondary pressure. Available with a vessel clamp to fix the GLP on a drum.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The GRP is a pneumatic agitator equipped with either a helical geared drive or a worm geared drive. It is used for homogenizing, dispersing, emulsifying and suspending of low- and medium viscosity materials in small containers. The agitator shaft is directly mounted on the shaft journal. Elastic operation, in other words: The speed of the agitator adapts to the viscosity of the media being mixed. Compact and easy-to-maintain construction as well as low weight allows an easy handling. Speed is sensitively and continuously adjustable, smooth start, insensitive to vapor, dust and smoke. Compressed air keeps all moving parts clean. Insensitive to heat, suitable for high ambient temperatures. Compressed air expanding in the air engine cools the agitator drive. The pneumatic agitators are explosion proof and overload proof until standstill. Type test certificate for explosive zone 0.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

The PP1 chips collector is used for the rapid collection of shavings and other metal parts, for cleaning the workplace, the machine or for the collection of metal parts from waste or ash. The collected metal parts can be removed by pulling the rear release button. Magnets for surface and railing cleaning clean halls and outdoor areas from magnetic parts and thus protect personnel and equipment

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

Modular dosing system for filling conductive liquids in packaging machinery. Advantages over mechanical systems • no moving mechanical parts • easy cleaning in comparison with piston fillers • easy adjustment of batch quantities • no mechanical forces are applied to the product Special features • short dosing times of up to 100 ms possible • filling quantities from 1ml to DN 10 • small dimensions of the transmitter • wide range of batch quantity with one nominal size • CIP / SIP ability up to 140°C • min. conductivity >1µS/cm • complete system Flexibility • DN 10, 15, 20, 25, 32, 40 • various connections are available e.g.: • aseptic connection according to DIN 11864-1 to 3 • TRI-CLAMP according to DIN 32676 • milk thread according to DIN 11851 • 3A approved MDS completely electronic • different housing for 6/12/18 measuring channels • software for Linear, Rotary and Single Start Machines • connection to operator terminal or PLC • direct control of the dosing valve • 24 VDC...

Request for a quote

BOPP & REUTHER MESSTECHNIK GMBH

Germany

The Dosing Mass flow Meter extends the range of Dosing Sensors with special attention to the dosage of non-conductive media and direct mass dosage. The devices are designed in a very compact way and can be connected directly to the Compact Controller. The sensor outputs are compatible to those provided by our magnetic-inductive flowmeter with Converter Card UV14. As a minimum configuration, 24 VDC supply, valve input and pulse output can be connected. The pulse factors are adapted to the magnetic-inductive flow meter, so that the devices can be interchanged easily. Advantages • compact design • direct measurement of mass • measurement of non-conductive media • very short dispensing time down to 250ms • high accuracy / repeatability • no moving parts • easy to clean compared with piston filler • product gentle filling Flexibility • DN 10, 15, 20, 25 • liquid temperature 0°C to 90 °C • different connections available such as: • Tri Clamp acc. DIN 32676 • Sanitary thread acc. DIN 11851

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The majority of plastics used today are very susceptible to the formation of electrostatic charges on the surface. The result of this is that the surfaces are strongly attractive to particles floating in the surrounding air. These adhering particles must be removed before painting. Dirt is difficult to remove from three-dimensional or structured surfaces using conventional methods. Components such as goods carriers, which are used continuously in circulating operation, are usually also difficult to clean on account of their geometry. The dynamic ionisation station has been developed especially for these applications. The goods carriers with the three-dimensional workpieces usually pass through the ionisation station standing on, or suspended from conveyor systems. Ionisation electrodes installed in the inlet and outlet generate positively and negatively charged ions, which are transported by the flow of air to the plastic surfaces. The static surface charges are neutralised as a result. The rotary cleaning nozzles located in-between remove adhering particles from the surfaces of the workpieces using cleaned compressed air. Dust and material particles are blown away by a pulsating air flow from different directions due to the rotation of the nozzles. This highly effective method enables even dirt on shaped parts to be cleaned off reliably. The particles cleaned off in this station are fed to a filtered extraction device by targeted air guidance.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Continuous flow pretreatment plants are designed for high throughput and consist of cleaning stages (degreasing), rinsing stages and possibly layer-forming processes such as phosphatisation. Continuous flow pretreatment Continuous flow pretreatment plants are universally usable. Their high throughput performances in particular make them interesting for many applications. Spraying rings apply different media to the components as they pass through. In the successive zones, therefore, the parts can pass through a cleaning programme tailored to the particular application that guarantees optimum and constant quality. Rippert builds continuous flow plants for small sheet metal parts up to large-scale drag cleaning with a high quality of workmanship. Multi-channel pretreatment plants are also possible, as is combined pre-cleaning by means of robots.

Request for a quote

ERC ADDITIV GMBH

Germany

ERC carburettor cleaner breaks down all deposits and soiling and is an indispensable tool for professional service in specialist workshops. The Effect During operation, impurities collect in the carburettor chamber and the carburettor parts. They can impair the function of the carburettor. The Result ERC carburettor cleaner is a special concentrate which was developed for the simple cleaning of residue and impurities. With a single use, all impurities are broken up and removed. The carburettor is then as clean as the day it left the factory. The benefits at a glance: - Cleans all carburettor parts - Is highly effective - Simple use for professional service in specialist workshops ERC carburettor cleaner can either be poured into the carburettor chamber (1:4 dilution in petrol) or into the dirty parts (1:1 dilution).

Request for a quoteResults for

Part cleaning - Import exportNumber of results

79 ProductsCountries

Company type

Category

- Cleaning machines, industrial (21)

- Cleaning, industrial (16)

- Vacuum cleaners, domestic (16)

- Environmental protection - machines and equipment (4)

- Filtering equipment and supplies (2)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Portable electrical pumps (2)

- Sandblasting equipment (1)

- Meat processing machines (1)

- Adjustment - machine tools (1)

- Dosing pumps (1)

- Engineering - industrial contractors (1)

- Hoses, pipes and tubes - plastic (1)

- Laboratory equipment and instruments (1)

- Magnets (1)

- Petrol (1)

- Punching machines, plastic (1)